Bioproduct Chemistry

Our research areas:

- Added value materials from biocolloids (e.g., foams, hydrogels, composites)

- Sustainable surface functionalization of cellulosics (e.g., textiles, barrier materials)

- Side-stream valorization (e.g., lignin, waxes, extracts)

FinnCERES - Flagship for boosting bioeconomy

Boosting the world’s bioeconomy by developing new bio-based materials with Aalto University and VTT, companies, and research organizations through a shared passion to create a sustainable future and a belief in innovations based on solid scientific foundations.

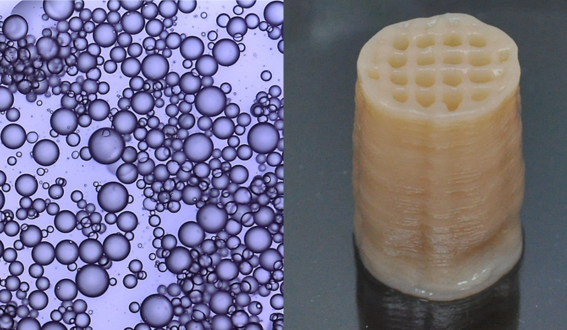

Added-value materials from biocolloids

Aiming for more sustainable use of natural resources, we work on the development of new value-added materials based on cellulose nanofibrils, hemicelluloses, and colloidal lignin particles to replace fossil-oil-based materials in areas ranging from packaging and coatings to tissue engineering.

Biocolloid projects

Sustainable surface functionalization of cellulosics

We explore different green approaches for surface modification. Nontoxic approaches for protective coating solutions with controlled breathability for surfaces like wood and textiles are explored. We investigate fundamental understanding of the surface interactions and film formation for the development of bio-based barrier materials.

Surface functionalization projects

Side-stream valorization

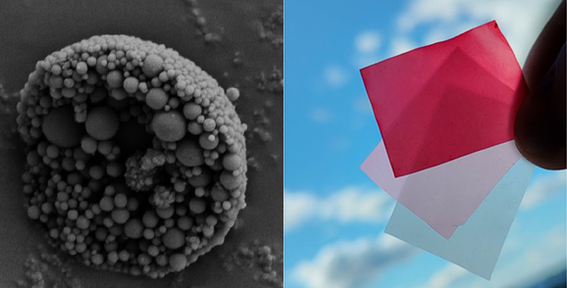

An important part of our research is devoted to the transformation of waste lignin from biorefineries and pulp industries into high-added-value products. The preparation, modification and utilization of lignin nanoparticles are at the core of this research line. Bio-based coatings, adhesives, and composites are some examples of commercial applications of colloidal lignin particles we are working on.

Components from bark extracts are also studied as biocolorants and for packaging, and other added-value applications. One project is to develop bio-based dyes and pigments to replace synthetic dyes commonly used in the textile industry.

Valorization projects

Research group members:

Join us!

Highly motivated MSc, doctoral or postdoctoral students interested in joining the team should contact Prof. Österberg (firstname.lastname@aalto.fi).

Chemistry research methods and new materials explored in summer student projects

Five summer students contributed to research projects in the Bioproduct Chemistry group in 2023, gaining experience and skills in research techniques, and materials identification and characterization.

Follow us:

Related content:

Fantastic Lypsy stools – and their illusory making techniques

A furniture collection celebrating the art of craft.

Lignin nanoparticles: A sustainable recipe for combining cellulose with hydrophobic polymers for advanced applications

The Bioproduct Chemistry team at Aalto University have designed a sustainable method to produce strong and flexible cellulosic films that incredibly maintain their strength even when wet.

Eco-glue can replace harmful adhesives in wood construction

A fast and energy-efficient manufacturing process results in a strong, non-toxic and fire-resistant adhesive—and a great opportunity for the Finnish bioeconomy.

Bio-based coating for wood outperforms traditional synthetic options

Researchers turn a non-toxic residue into wood coating that resists abrasion-, stain-, and sunlight.

Academic co-operation on the boreal forest belt launched to accelerate innovation and adoption of bio-based solutions

University of British Columbia (UBC), Aalto University and VTT are joining their strong expertise on bio-based materials by launching the Boreal Alliance. The collaboration is realized via the Finnish FinnCERES Flagship and the BioProducts Institute at UBC.

Monika Österberg starts as Head of Department at BIO2

Professor Monika Österberg has been nominated as the Head of Department at the Department of Bioproducts and Biosystems (BIO2), starting January 1, 2021. Her term is for three years. She has acted as Vice Head of Department since the beginning of the year 2020.

Using lignin to replace fossil materials

Ball-like lignin particles developed by researchers open up completely new possibilities for the utilisation of lignin.

Breakthrough in lignin research: spherical particles multiply enzyme efficiency

Lignin, a pulp industry by-product, could replace fossil materials.

Student summer projects provide insights into bioproduct chemistry research

Three summer students contributed to research projects in the Bioproduct Chemistry group in 2022, gaining experience and skills in research techniques, and materials identification and characterization.