Biorefineries

Research themes:

1. Biomass fractionation - chemical pulping refineries and novel fractionation processes:

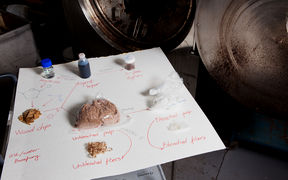

We investigate radically new energy and resource efficient production technologiesfor chemical pulping, e.g. Kraft-Oxygen Delignification (KrOxy) process and new dissolving pulp technologies.In addition, our research group develops novel biomass fractionation processes based on the utilization of Biomass valorisationsupercritical water and green solvents, e.g. gamma-valerolactone (GVL).

- Investigation of novel fractionation technologies such supercritical water, and Organosolv fractionation methods simultaneously with the optimization of the conventional kraft pulping process;

- Pulp characterizations, bleaching, purification (hemicellulose removal) and the adjustment of pulp properties.

2. Biomass valorisation:

Cellulose: We study conversion of cellulose e.g. into man-made cellulose fibers and all-cellulose composites.

Hemicelluloses: Our research topics include the valorisation of xylan from alkaline extractions, production of xylo-oligosaccharides and catalytic conversion of biomass-derived sugars into furans.

Lignin: Lignin is an interesting biomass component which can be converted into valuable products such as bio-oil. Lignin-cellulose blends can be used e.g. as precursor fibers for carbon fibers, or as natural dye in textiles.

- Dissolving pulp production according to existing and new protocols

- Production of man-made cellulose fibers from virgin cellulose pulp and cellulosic textile wastes by the Lyocell spinning process with emphasis on the Ioncell® fiber process

- Chemical modification of regenerated cellulose fibers

- Production of furanic-based platform chemicals from biomass-extracted hemicellulose

- Production of bio-oil and monoaromatic compounds from various lignin sources by catalyzed and uncatalyzed hydrothermolysis.

Our versatile reactor portfolio enables flexible pulping experiments from small lab-scale (30 mL) to pilot scale (10 L), including both traditional (prehydrolysis) kraft and novel Organosolv processes. Elemental-Chlorine-Free (ECF) and Total-Chlorine-Free (TCF) bleaching techniques are readily available.

Our flagship research in biomass valorization is the production of novel man-made cellulose fibers for the circular economy by the dry-jet-wet spinning Ioncell® process, which convert cellulose from virgin wood pulp or cellulosic textile waste into high-quality, high-strength textile fibers. In addition, our research group is equipped with fiber characterization equipment and yarn spinning machinery. We also investigate in the conversion of extracted hemicelluloses and lignin to high value products such as furanic platform chemicals, monoaromatic compounds and bio-oil. Our lab developed advanced chromatography methods (HPLC, CE, IC, GPC) for comprehensive analysis of complex product mixtures.

Examples of ongoing research projects:

- Trash-2-Cash (EU Horizon 2020)

- SolvRec (Business Finland)

- iCom (Business Finland)

- ALL-CELL (FiDiPro, Prof. Tatiana Budtova)

- WoCaFi (ERC starting grant, Dr. Michael Hummel)

- Tekide (ERDF)

Ioncell

Ioncell-F is a technology that turns used textiles, pulp or even old newspapers into new textile fibers sustainably and without harmful chemicals. The process converts cellulose into fibers which in turn can be made into long-lasting fabrics.

Read more about the Ioncell process and our projects at ioncell.fi!

Awards:

The Ioncell-F process was granted the Global Change Award 2016 by the H&M Conscious Foundation, the Paper Recycling Award 2015 of the European Recovered Paper Council (ERPC), and the DIA Innovation Award 2018.

γ-valerolactone biorefinery

γ-valerolactone pulping is a novel organic solvent fractionation process developed by Professor Herbert Sixta’s Biorefineries research group.

Herbert Sixta, head of the research groupWe urge not only for investment in pulping research, but also for the commitment of young researchers.Together we make pulping great again!

The textile industry needs sustainable fibers produced from renewable or recycled sources, which can be recycled at the end of their life and which do not produce micro-plastics. The demand for textile fibers is growing due to population growth and living standards. Currently, most textile fibers are synthetic, e.g. polyester, and are made from non-renewable sources. Cotton cultivation causes environmental problems due to the high consumption of irrigation water, pesticides and fertilizers. When textiles made of synthetic fibres are washed and worn, small fragments are released, causing microplastic contamination.

Aalto University offers the opportunity to study the raw material chemistry and process engineering necessary for the development of a sustainable textile industry, thereby combining materials research with textile and fashion design.

Production of commodities from biomass is the most viable option in the foreseeable future to mitigate the climate changes.

The raw materials of novel man-made cellulose fibers that we are developing in our research group are virgin pulp and recycled cotton waste. Cellulose pulp is made from smaller trees, and thinning stimulates the growth of remaining trees, thereby increasing carbons storage. When pulp is used for long-lasting products like textiles, the carbon is stored in the product. The recycling of cellulosic textiles even prolongs the carbon sink

Research group members:

Related content:

Professor Emeritus Herbert Sixta: “The most important task of a professor is to educate young people, to help them build their career”

After an extensive career in academia and the forest-based industries, Professor Herbert Sixta has retired. Having worked in Austria for 25 years, Sixta arrived to Aalto in 2007, where his research in biorefineries helped create, among other things, the Ioncell process, a technology that turns used textiles, pulp, and paper into new textile fibres sustainably and without chemicals.

Biorefineries and Herbert Sixta in spotlight at 2022 seminar

Biorefineries research group annual seminar presented the latest developments in forest-based, sustainable refineries and analytical tools.

Fibre made from recycled cloth towels and hemp stronger than cotton

The tensile strength of fibres created with the Ioncell method is up to 2.5 times more than that of cotton, while an Ioncell knitted fabric made from recycled hemp withstands abrasion for twice as long as normal hemp fabric.

Solving the systemic challenges in textile and fashion industry

We need systemic and fundamental changes in the textile and fashion industry’s business model, including a deceleration of manufacturing and the introduction of sustainable practices throughout the supply chain; decreasing clothing purchases and increasing garment lifetimes.

Take Finland’s lead and choose clothes you don’t have to feel guilty about

An Aalto University-designed and -produced dress made of birch trees shows how one day we will all look—and feel—good in sustainable fabrics

Jenni Haukio to wear gown made of sustainable Ioncell material at December’s Independence Day reception

Ioncell is a new technology that creates high-quality textile fibres from wood or recycled materials.

President Macron received a scarf made from old jeans with Ioncell-F technology

The sustainable textile process was introduced to the President during his visit to Aalto University on 30 August 2018.

”Koivikko” scarf paving way for new textile fibres made out of renewable and traceable birch

Professor Herbert Sixta donated an Ioncell scarf to Sirpa Välimaa, Product Manager Dissolving Pulp, Stora Enso Oyj, in PulPaper Conference on 31 May in Helsinki.

High performance man-made cellulosic fibres from old newspapers

Increasing consumption requires new ways to recycle waste. In Aalto University old newspapers were converted to textile.

Upcycling ‘fast fashion’ to reduce waste and pollution

Aalto’s Ioncell team presents their work at a meeting of the American Chemical Society.

Fibres from textile waste to be turned into new attractive consumer products

Trash textiles are a valuable resource that should not be left untapped. Aalto and VTT are participating in an EU project called Trash-2-Cash.

Awarded method makes textile fibre from waste cotton

A greener textile industry requires expertise in chemistry, design and economy, stresses Herbert Sixta who leads the development of Ioncell-F.

A process revolutionising cotton recycling wins the H&M Global Change Award

The Ioncell-F™ process adapted for the conversion of waste-cotton into new textile was awarded as one of five winners among 2,700 proposals.

Luxury fibre from recycled cardboard

Prize-winning spinning method can reduce the environmental hazards of textile production.