DigiTwin Lab

The DigiTwin Lab conducts an impactful on the various realms of digitalization of industry, including the Industrial Internet of Things, Digital Twins, Extended Reality interfaces, and Metaverse. The lab is notable for its deep collaboration with the industry, including several industry-university collaboration projects, such as DigiTwin, Machinaide, Co-Des, and Necoverse. Furthermore, we have received several donations that allow experiments with a realistic industrial environment: an overhead crane from Konecranes, an elevator from Kone, and a motor and generator set from ABB. These contributions enable the lab to simulate various industrial processes realistically. The DigiTwin Lab also provides a specialized area for the autonomous and collaborative operation of robots.

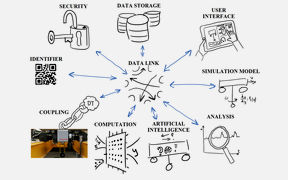

The key research topics of DigiTwin Lab are as follows:

1) Digital Twins and Digital Twin Web

Digital Twins link information from real-world entities behind a single access point making information accessible. Digital twins can have several features depending on their use case, and these features are described in a standardized description document. The purpose of Digital Twin Web is to make these Digital Twins discoverable. In addition, Digital Twin Web provides methods to enable communication and collaboration between digital twins. Our current research investigates the trust and interoperability of digital twins.

2) Industrial Extended Reality interfaces

Industrial Extended Reality (XR) interfaces represent a transformative approach in the realm of human-machine interaction. In this realm, we explore how XR technologies like virtual reality (VR), augmented reality (AR), and mixed reality (MR) can revolutionize industrial operations. Our research includes developing immersive interfaces for tasks such as on-site machine control, training simulations, and remote operation. These interfaces are designed to improve efficiency, safety, situational awareness, and decision-making in industrial settings

3) Industrial Information Integration

Industrial Information Integration refers to the process of collecting, harmonizing, and combining diverse information from various sources within an industrial setting. Industrial information integration is a complex but essential aspect of Industry 4.0 initiatives, enabling organizations to harness the full potential of data for improved operational efficiency, predictive maintenance, and informed decision-making. The industrial information integration involves the aspects, including data source perception, data format not standard definition, data modelling, and platform development, leveraging advanced ICT technologies, encompassing IoT devices, cloud-based solution, edge computing, and semantic technologies.

4) Metaverse

Metaverse is a new emergent interdisciplinary approach to achieving integrated systems, and our definition for the metaverse is as follows: “a continuum of physical and virtual systems, interconnected and intertwined in ways that allow for seamless transitions and interactions. It stands distinct from merely virtual environments and virtual reality in its depth of connection to the physical world, and its constant synchronization and reflection of real-world dynamics.” Our exploration in the Metaverse focuses on creating a symbiotic relationship between the virtual and physical worlds, enabling users to experience and manipulate virtual representations of physical objects and processes with high fidelity for industrial applications.

Aalto University invests in international cooperation in digital twin research

The MACHINAIDE project explores the prerequisites for collaboration between digital twin devices made by various manufacturers and for the efficient combination of information from them.

Aalto University developing digital twins in manufacturing industry

Aalto University develops digital twins for the manufacturing industry together with Konecranes, Ideal PLM, Siemens, Remion and RD Velho.Aalto University is creating a network of companies interested in developing digital twin technology. Start-ups and SMEs offering products or services in analytics, product development and maintenance are of special interest, but the network welcomes everyone interested in the field.

Highlights

New Flagship programme protects water resources through digital twins.

‘The Flagship is a welcome and an important opening for increasing the effectiveness of the water sector. It promotes the digitalisation of the water sector, opens doors to young researchers, and serves as an ecosystem for companies in the field as well as for societal actors’, notes Professor Harri Koivusalo.

Digital twin for optimizing the carbon balance in wastewater treatment

Researchers at Aalto are creating a digital model for automatic continuous predictive process simulations supporting wastewater treatment plant operation in a new project called DIGICARBA. The proposed digital tool will have a wastewater treatment process model connected to continuous data transmission from the Helsinki wastewater treatment plant.

Digital twin of electric motors enhances industrial processes

The energy transition is rapidly increasing the global rate of electrification. Aalto University is involved in an ABB R&D project in which digital twins are being created for electric motors and frequency converters.

Professor Kari Tammi’s group develops digital twins for industrial use

A digital twin refers to a virtual model of a machine, equipment or even a whole production plant.

Digital twin documentation by the project partners

Konecranes

How digital twins are transforming business (Blog 3/2019)

Digital twins – a new standard in industrial production (WayUp 29.11.2017)

Remion

Miten digitaalinen kaksonen voi toimia tuotekehityksen apuna? (23.1.2019)

Digitaalinen kaksonen nostaa laitedatan hyödyt uudelle tasolle (3.12.2018)

Minkälaista hyötyä digitaalisista kaksosista voi saada teollisuuden digimurrokseen? (19.11.2018)

Aalto

Aalto University to establish network of companies interested in digital twin development (9.1.2019)

Other interesting reading on digital twins

Koneet saivat kaksosen, jonka avulla tuotekehitysaika lyhenee (Talouselämä 24.10.2018)

- The basics of the digital twin concept in Finnish

- Includes text and video (1:46)

Announcing the public preview of Azure Digital Twins (Microsoft 16.10.2018)

- Using Microsoft Azure as a backend platform for orchestrating digital twins

- Includes text and video (11:46)

Digitaalinen kaksonen - ratkaisu kaikkiin ongelmiisi vai tiedonhallintaa rajapintojen avulla? (Tekniikka&Talous 23.5.2019)

People