In the supply chain management CAPSTONE course students worked on future challenges

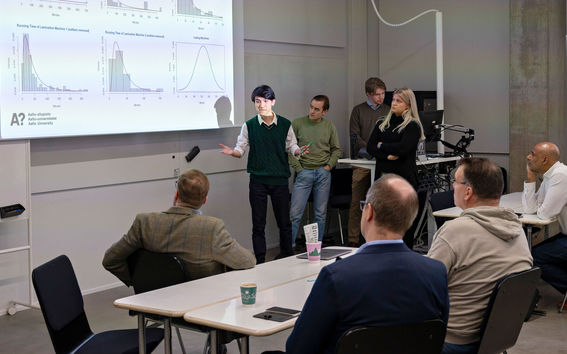

During the “Future-proofing supply chains” Capstone course in Supply chain management, students worked in teams on real-life challenges offered by the participating companies. Here we present two project assignments that the students solved. The assignment presented by Reima was very analytical. Most of the assignment consisted of calculations (forecast, inventory management, distribution network optimisation). The project for Meluton was a combination of quantitative (calculations for managing basic functions related to capacity, performance, etc.) and qualitative analysis.

This Master’s level course was offered in a format of 100% pure group working. ‘Students did not have any other assignments or exercises, but they could concentrate on the group project, which included providing a proposal for the project plan, writing the final report, and giving the final presentation,’ tells Katri Kauppi, Professor in charge of the course. ‘The students had to arrange by themselves their progress in a six-week tight schedule.’

Focus on distribution channel optimization in Case Reima

Student Yifan Wang tells that Reima tends to find an optimal solution in its warehouse network while maintaining its sustainable growth, strengthening its foothold in key markets, and developing new business channels. ‘Acting as external consultants, we needed to provide a research report about the warehouse locations and distribution plan by using historical data and transportation costs in different channels. Our consideration includes the delivery cost, lead time efficiency, feasibility, and environmental footprints.’

Our team (Linh Hoang, Petriina Heikkinen and I) received plenty of data from the company and they gave us an introduction to their current situation and problem. ‘During the project work, whenever there was anything unclear, we could contact the company directly for any clarification. Meanwhile, we could also ask the professor and teacher assistant for guidance when we fall into the puzzle.’

Yifan Wang tells that he learnt the elements to be considered in a real-life distribution plan. ‘It was not only about the distance from warehouses to final markets, but also about the delivery lead time, local labor cost, infrastructure level, and environmental impact. The feasibility and final arrangement connected closely to sustainability, as the carbon emission footprint was one of the important targets the company wanted to achieve.’

‘The case is a simulation of consulting work. We received real data from the company and I realized that real-life consulting can never be a simple problem-solving exercise. We had to make a lot of reasonable assumptions based on the data and a perfect solution may never be achieved due to limitations trade-off. Additionally, I learned something about forecasting. We adjusted our forecast methods with the feedback from the company and the external reading materials,’ Yifan Wang tells.

Focus on inventory planning in Case Meluton

Minttu Toropainen belonged to the team which worked for Meluton. ‘Our assignment was to act as consultants and double the company's turnover in the given time. Our customer company was Meluton, a Finnish company specialising in sound and heat insulation. They did not have a specific area in which they wanted a change, but they did point out certain areas of the company for improvement. These included operative functions and practical solutions.’

Minttu Toropainen and her team were given relatively a lot of freedom to tackle the areas they considered most appropriate for achieving our goal. ‘So we started thinking about this assignment from the perspective of inventory planning, capacity and agile supply chain management. We designed for the company, for example, a new type of floor plan for more efficient storage, a simulation model for maximising product capacity, and other smaller improvement points for operational activities, among other things. These included the implementation of Lean methods to improve efficiency.’

‘The visit to the factory was one of the highlights of the course, because it allowed me to familiarise myself with a completely unfamiliar field, so that I could properly understand what Meluton is currently doing as a company. What I especially liked about the course was that it allowed us to use the lessons learned in theory in concrete terms while brainstorming a solution for the customer.’

Great learnings for the future working life

Yifan Wang who worked on the Case Reima enjoyed the course as it was so real that it could make him prepared for the work life before he steps out of the university. ‘It was not like the traditional courses in that we used what the teacher taught during the lecture in the exercise and exam but required us to use everything we knew to solve the case. The case itself is so interesting under a business scenario that I could apply the tools I learned from other courses like Business Analytics to the model and analysis.’

Minttu Toropainen from Team Meluton tells that the course allowed them to complete a real-life project in practice but be still supported both by the teacher of the course and the company, which was really nice. ‘We first had a meeting about what we are going to do with the company, after which the teacher supported and guided us in the right direction, which was nice in the sense that we had not done such a project ourselves before. At the end, we presented our output to three representatives of Meluton, who were allowed to give comments and feedback on how they thought we had performed the assignment.’

Nicklas Susila, who worked in the same team with Minttu Toropainen, tells that what was special in this course was that they had real life cases from which the could choose from what they want to work on. ‘This combined with the possibility to act as a consultant and getting to visit the company premises to really see what’s going on in the operations side was really interesting. It was great that we had the possibility to communicate with the case company by asking questions, data and their wishes for the project. This is also something I think many students appreciate.’

Jussi Niemelä,CEO of Meluton, is pleased with the course. ‘The students’ enthusiasm, good questions and perspectives were valuable to us. There were good and practical insights in the proposed solutions, and Meluton intends to continue cooperation with Aalto University by offering project assignments to students,’ he says.

Department of Information and Service Management

The Department of Information and Service Management refers to the creative use of information and digital technology in business and the move from industrial to service dominant forms of production.

Read more news

Join the Unite! Virtual Education Summit- Registration now open

Join us in shaping international collaboration! This online event takes place 12 March, 2026.

Apply Now: Unite! Visiting Professorships at TU Graz

TU Graz, Austria, invites experienced postdoctoral researchers to apply for two fully funded visiting professorships. The deadline for expressions of interest is 20 February 2026, and the positions will begin on 1 October 2026.

Elina Pyylampi wants to combine renewable energy solutions and commerciality

The first-year student in Electrical Power and Energy Engineering wants to work with renewable energy and electrical systems.