Public defence in Electronic and Digital Systems, M.Eng. Obert Golim

When

Where

Event language(s)

The title of the thesis: Low-Temperature Solid-Liquid Interdiffusion Bonding for Heterogeneous Integration

Thesis defender: Obert Golim

Opponents:

Prof. Andreas Leineweber, Technische Universität Bergakademie Freiberg, Germany

Dr. Anne Jourdain, IMEC (Inter-University Microelectric Centre), Belgium

Custos: Prof. Mervi Paulasto-Kröckel, Aalto University School of Electrical Engineering, Department of Electrical Engineering and Automation

Heterogeneous integration is an essential concept in the microelectronics industry, particularly with the ever-growing trend toward functional and compact device design. However, this approach presents challenges when incorporating materials with differing characteristics, particularly regarding temperature-induced constraints for the assembly process. As a result, low-temperature bonding process becomes an essential part of the toolbox to realize the full potential of heterogeneous integration.

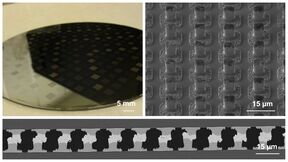

This dissertation focuses on the low-temperature bonding technique based on the solid–liquid interdiffusion (SLID) technique utilizing Cu–Sn–In metallurgy. The eutectic behaviour of Sn–In allows a significant reduction of the bonding temperatures from a typical bonding temperature above 250 °C down to 150 °C.

Microstructural observations of the resulting joint from the low-temperature process reveal homogeneous interface featuring an intermetallic phase with a remelting temperature of more than 450 °C, which makes it thermally stable. Electrical measurements of the resulting bond demonstrate a small resistance that is comparable to those obtained from the well-known Cu–Sn bonding/soldering technique, underscoring the capability of this low-temperature process for vertical integration. The bonds also exhibited hermeticity potential for microelectromechanical system (MEMS) or microoptoelectromechanical system (MOEMS) packaging.

Some challenges in the implementation of the low-temperature bonding process have been identified, including limitations for process integration, squeeze-out, and defect formations. These issues can be mitigated through optimization of the design and processing parameters. Despite these challenges, the results from this work highlight the prospect to fully demonstrate the capabilities of heterogeneous integration by addressing temperature-induced limitations.

Keywords: Low-temperature bonding, heterogeneous integration, Cu-Sn-In metallurgy, SLID, interdiffusion, intermetallic, interconnects, hermeticity.

Thesis available for public display 10 days prior to the defence at: https://aaltodoc.aalto.fi/doc_public/eonly/riiputus/

Contact: obert.golim@aalto.fi; +3585047360225

Doctoral theses in the School of Electrical Engineering: https://aaltodoc.aalto.fi/handle/123456789/53