Green Factory - towards carbon neutral production (GREEF)

Abstract

Climate change and its management is the most significant challenge facing our society. The Finnish government has set a goal for a carbon-neutral Finland by 2035. The technology industry has published a low-carbon roadmap towards this goal. The means of the emission reduction mostly relate to electrification of processes and machines, improving energy and material efficiency, the circular economy and the use of digital solutions. This requires large-scale industrial R&D investments in the green and digital transition. Environmentally friendly, low-carbon industrial production will be an increasingly important competitive factor in the international market.

Achieving an international competitive advantage requires a joint project between Finnish companies and research institutes.

The GREEF co-innovation project involves Aalto University, The University of Oulu, VTT Technical Research Centre of Finland, and seven Finnish companies of different sizes: SEW Industrial Gears Oy, AGCO Power Oy, Proventia Oy, Leden Group Oy, Delva Oy, EQ System Scandinavia Oy and Componenta Oyj. The project will help companies reduce the environmental impact of their operations and products and accelerate them towards their low-carbon and export growth targets. The project covers a number of green industry themes that apply to each company. While companies focus on their most relevant themes, the GREEF research ecosystem increases the impact on the consortium and the industry as a whole.

The project combines industrial and scientific research in the best possible way.

The results provide best practices and models for:

- sustainable branding in the industrial market;

- carbon footprint calculation in manufacturing environment and supplier network;

- energy-efficient production control and supply chain;

- the suitability and environmental impact of metal AM methods as a manufacturing method.

The emerging know-how enables better identification of the environmental impact of the manufacturing industry and significant changes in operations and products that improve sustainability and competitive advantage.

GREEF webinar presentations

Materials for the presentations given in the 29 November 2023 GREEF webinar are available below:

| WP1 Green factory from branding perspective |

| Task 1.1 State of the art in sustainable industrial branding |

| Task 1.2 Green industrial branding ecosystems |

| Task 1.3 Methods for communicating environmentally sustainable industrial brands |

| Task 1.4 Carbon handprint from a business perspective |

| WP2 Carbon footprint (CF) calculation |

| Task 2.1 State of the art in industrial CF calculation |

| Task 2.2 CO2 and other emission sources and factors in the factory and supply chain |

| Task 2.3 CF calculation for manufacturing industry |

| Task 2.4 CF calculation for case companies |

| WP3 Sustainable production management |

| Task 3.1 Usability study of CF calculations in machine shops |

| Task 3.2 Implementation procedure of CF calculations |

| Task 3.3 Demonstration environment |

| Task 3.4 Sustainable and climate-friendly supply chain models |

| WP4 Industrial renewal in manufacturing processes and methods |

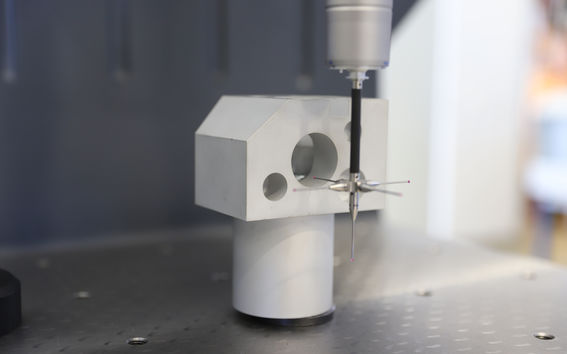

| Task 4.1 Technological capability and potential of metal additive manufacturing (AM) |

| Task 4.2 Environmental impacts and benefits of metal AM |

| Task 4.3 Remanufacturing |

- Matikainen, M. (2022). Lastuavan työstön energiankulutus. (Kandidaatintyö, Aalto-yliopisto). https://aaltodoc.aalto.fi/handle/123456789/116008

- Kondakov, M. (2023). Terästeollisuuden alkutuotannon ympäristövaikutukset. (Kandidaatintyö, Aalto-yliopisto). https://aaltodoc.aalto.fi/handle/123456789/123248

- Niemi, A. (2023). Uudelleenvalmistus. (Kandidaatintyö, Aalto-yliopisto). https://aaltodoc.aalto.fi/handle/123456789/123616

- Pulli, O. (2022). Ympäristöarvojen huomiointi hienokuormitus- ja tuotannonohjausjärjestelmän käyttöönotossa. (Diplomityö, Oulun yliopisto). https://jultika.oulu.fi/Record/nbnfioulu-202206152849

- Erkkonen, J. (2022). Becoming rightfully green: how industrial companies legitimate their green brands for their customers? (Master’s thesis, University of Oulu). https://jultika.oulu.fi/Record/nbnfioulu-202206142769

- Kangas, M. (2023). Environmentally sustainable brand identity co-creation in an industrial context. (Master’s thesis, University of Oulu). https://jultika.oulu.fi/Record/nbnfioulu-202302151156

- Ruokostenpohja, M. (2023). Sustainability in communications content: the frames of handprint in corporate communication and branding. (Master’s thesis, University of Oulu). https://jultika.oulu.fi/Record/nbnfioulu-202306132428

- Silva, J. (2023). Comparative life cycle inventory of CNC machining and powder bed fusion additive manufacturing. (Master’s thesis, Aalto University). https://aaltodoc.aalto.fi/handle/123456789/119451

- Alieva, E. (2023). Analysis of emissions in foundries with carbon footprint calculator. (Master’s thesis, Aalto University). https://aaltodoc.aalto.fi/handle/123456789/119366

- Ahmed, T. (2023). EU carbon border adjustment mechanism and production location. (Master’s thesis, Aalto University). https://aaltodoc.aalto.fi/handle/123456789/121694

- Ojansivu, I., Saraniemi, S., & Erkkonen, J. (2022). Legitimating ’invisible’ sustainable B2B brands in domesticated markets/networks. Presented at the 38th Industrial Marketing and Purchasing Group Conference (IMP), 30 August – 2 September 2022, Florence, Italy.

- Ojansivu, I., Saraniemi, S., Erkkonen, J., & Autio, J. (2023). Legitimating collective change in reluctant global networks. In 39th Industrial Marketing and Purchasing Group Conference (IMP), 22-25 August, Manchester UK.

- Ruokostenpohja, M., Saraniemi, S., Vatanen, S., & Väinämö, M. (2023). Carbon handprint as a tool for framing sustainability in B2B brand communications. In 39th Industrial Marketing and Purchasing Group Conference (IMP), 22 – 25 August, Manchester, UK.

- Peltokorpi, J., Vatanen, S., & Glock, C. H. (2023). Greenhouse Gas Accounting for Manufacturers. In International Conference on Flexible Automation and Intelligent Manufacturing (pp. 912-919). Cham: Springer Nature Switzerland. https://link.springer.com/chapter/10.1007/978-3-031-38165-2_105

- Ahmed, T., & Niemi, E. (2023). EU carbon border adjustment mechanism under economies of scale. In 27th International Conference on Production Research (IJPR), 23 – 28 July, Cluj Napoca, Romania.

- Reijonen, J., Silva, J., Pulli, O., Hahtonen, K., Ulkuniemi, J., Niskanen, J., Puukko, P., & Metsä-Kortelainen, S. (2023). Comparative Life Cycle Inventory of PBF Additive Manufacturing and CNC Machining. In EPMA Proceedings 2023 & EPMA Congress and exhibition, 1-4 October, Lisbon, Portugal.

- Puukko, P., Hepo-oja, L., Vatanen, S. et al. Case study of the environmental impacts and benefits of a PBF-LB additively manufactured optimized filtrate nozzle. Sci Rep 14, 22183 (2024). https://doi.org/10.1038/s41598-024-73201-5

- Jaber, M. Y., & Peltokorpi, J. (2024). Economic order/production quantity (EOQ/EPQ) models with product recovery: A review of mathematical modelling (1967-2022). Applied Mathematical Modelling. https://doi.org/10.1016/j.apm.2024.02.022

- Maukonen, M. (2022). 3D-tulostuksella kestävän kehityksen mukaista kilpailuetua. Prometalli 4/2022. https://www.prometalli.fi/natiivi/3643/3d-tulostuksella-kestavan-kehityksen-mukaista-kilpailuetua

- Puukko, P., Hepo-Oja, L., & Lindqvist, M. (2023). Process Parameters Significantly Reduce Carbon Footprint. FonMag 3/2023. https://formnext.mesago.com/frankfurt/en/themes-events/fonmag/fonmag_articles/articles/delva.html

- Ruokostenpohja, M. (2023). Kädenjälki teollisuusyritysten viestinnässä ja brändissä. Oulun yliopiston blogi. https://www.oulu.fi/fi/blogit/oulu-business-school-fi/kadenjalki-teollisuusyritysten-viestinnassa-ja-brandissa

- Dang, J. (2023). Sustainable Supply Chain Management: A Shared Future. Interview conducted by Ilkka Ojansivu. Young Leaders for Sustainable Business. 23 August 2023. https://www.youngleadersforsustainablebusiness.com/post/sustainable-supply-chain-management-a-shared-future

- Peltokorpi, J. (2022). Green Factory – kohti hiilineutraalia tuotantoa (GREEF). Business Finland Sustainable Manufacturing -ohjelmapäivä, 25/5/2022. https://mediabank.businessfinland.fi/l/dPqtq9CXFWbB/f/5PP8

- Saraniemi, S. (2022) GREEF (Green Factory – kohti hiilineutraalia tuotantoa). Suomen Levynmuovauksen Yhteistyöryhmä FinDDRG:in Levytekniikan teemapäivä, 6/10/2022. Materia 5/2022, p.34. https://vuorimiesyhdistys.fi/wp-content/uploads/2023/01/Materia522.pdf

- Peltokorpi, J. (2023). Greenhouse gas accounting for manufacturing factories and supply chains. TU Darmstadt Brown Bag Seminar, 6/2/2023.

- Peltokorpi, J. (2023). Green factory – towards carbon neutral production (GREEF). Sustainable Industry X (SIX) Morning Coffee, 15/2/2023.

- Larkiola, J. (2023). Ympäristönvaikutusten huomioiminen tuotannonohjauksessa. Teknologiateollisuus ry:n Ohutlevypäivät, 18/4/2023. https://teknologiateollisuus.fi/en/node/27387

- Saraniemi, S. (2023). B2B-brändi teollisuudessa – miksi ja miten? Business Finland, Global Advisors’ Wednesday Corner, 14/6/2023.

- Puukko, P. (2023). Metallien 3D-tulostuksen ympäristövaikutuksista. Teknologia 23 -messut, 7/11/2023. https://teknologia.messukeskus.com/ohjelma/cd53ff220/metallien-3d-tulostuksen-ympristvaikutuksista/

- Peltokorpi, J. (2023). Green Factory - towards carbon neutral production (GREEF). Business Finland Sustainable Manufacturing closing seminar, 27/11/2023. https://mediabank.businessfinland.fi/l/dPqtq9CXFWbB/f/kJ6N

Funding

Total budget is about 4.8 MEUR, of which Business Finland support is about 2.5 MEUR.

In addition to research organizations, the consortium includes 7 Finnish companies.

The project is part of Business Finland's "Sustainable Manufacturing Finland" program.