Microfabrication

Our research areas:

- Micro- and nanofabrication

- Microfluidics and wetting

- Coatings and surface treatments

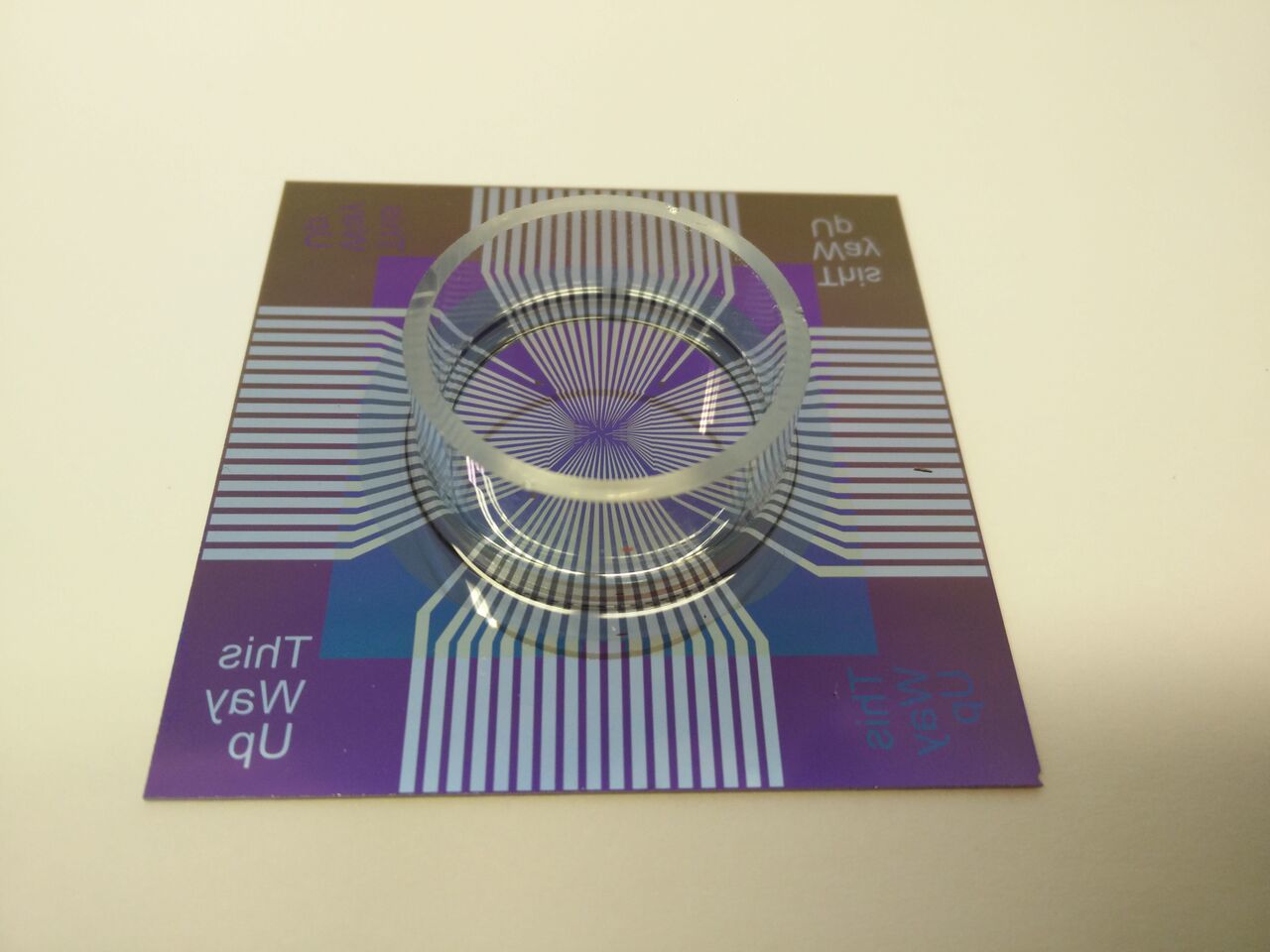

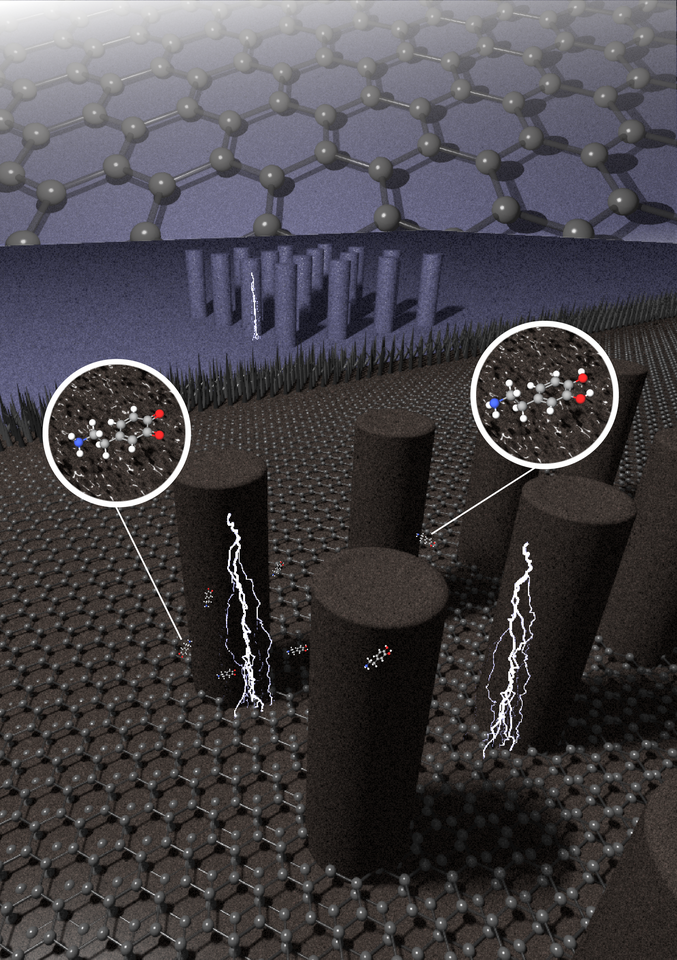

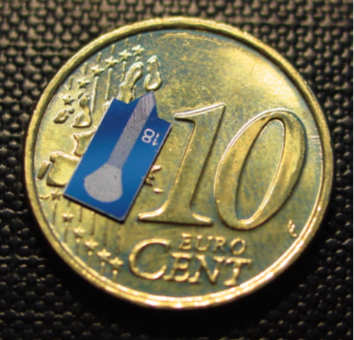

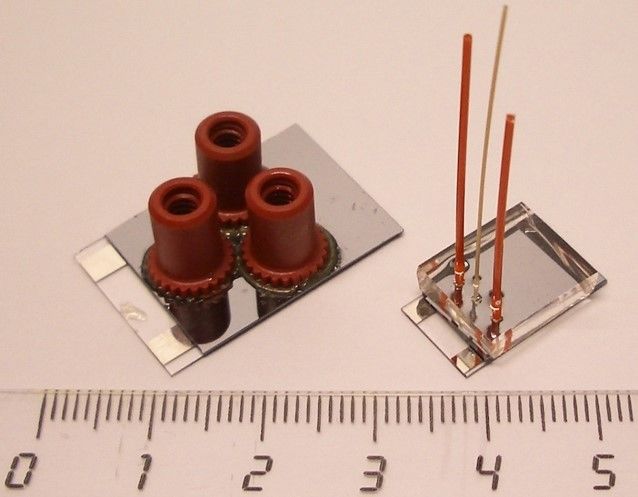

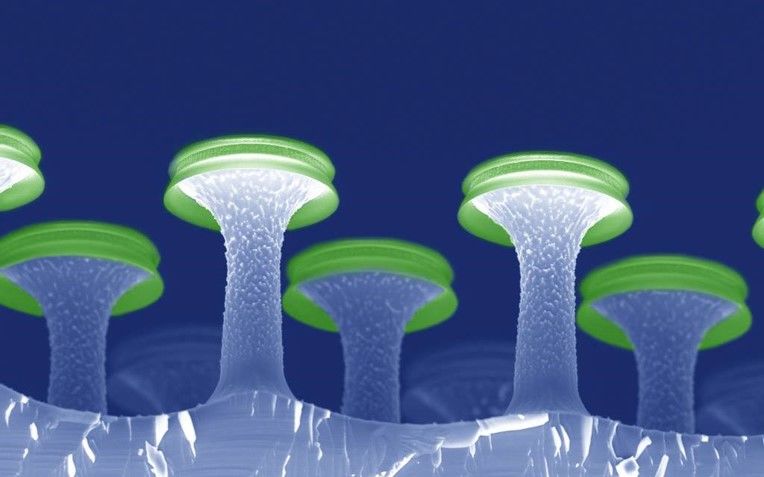

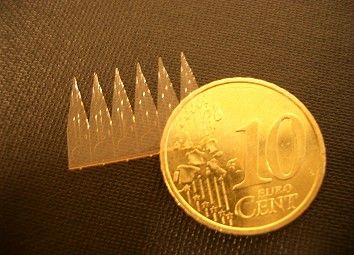

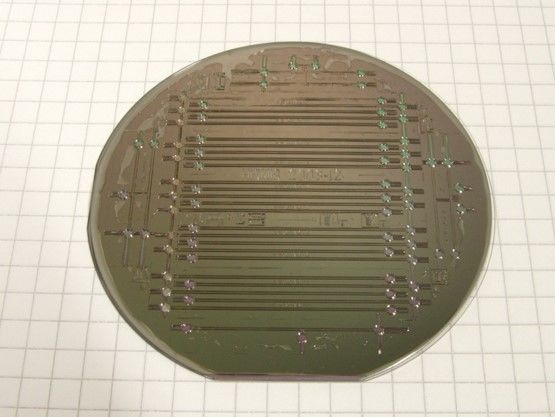

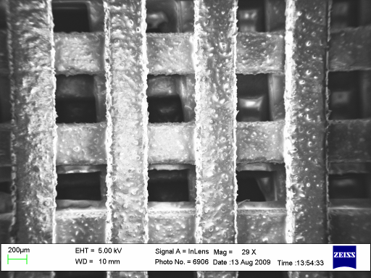

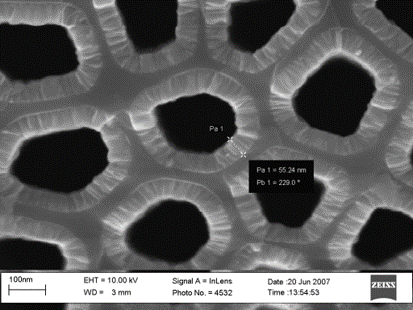

We employ a wide range of micro- and nanofabrication tools at Aalto Nanofab to create structures, devices and surfaces for fluidic, thermal, and biological applications. We have projects on neurons-on-a-chip (MEAs, carbon microelectrodes, dopamine analysis), carbon-MEMS (pyrolytic SU-8), superhydrophobic surfaces (blood repellency, icephobicity, antifouling and oleophobicity), foam materials (thermal insulation), single cell trapping (patterned superhydrophobic surfaces), flexible devices (metallization of elastomers).

Materials we work with:

- Silicon (bulk and SOI), Pyrex, Kapton, Aluminum as substrates

- AZ positive resists (also with image reversal), SU-8 and NXT15 negative resists

- PDMS and thiolenes for replica moulding

- Plasma Teflon and spin coated CYTOP for hydrophobic coatings

- SAMs made by wet and dry techniques

- Plasma deposited carbon materials (DLC, nc-C, ta-C)

- UV-sensitive sol-gel materials (SiO2, Al2O3)

- ALD films: TiO2, SiO2, Al2O3, TiN, NbN, Pt, nanolaminates

- Metals (Al, Cr, Cu, W, Pt) by sputtering and evaporation

Our work at Micronova cleanroom

We work on silicon, glass and polymer technologies, utilizing the Micronova cleanroom. Micronova is the largest research cleanroom in northern Europe with its 2600 m2 of class 10-class 1000 space, shared between VTT and Aalto University. Micronova is equipped with a wide range of processing tools for MEMS, CMOS, III-V and polymer technologies.

Examples of our equipment:

- optical lithography with backside alignment (Süss MA-6)

- DRIE (Oxford 100 cryo and STS Bosch) and RIE (Oxford 80)

- PECVD (Oxford 80)

- ALD (Picosun R200 and Beneq TFS 500 thermal and Beneq TFS 500 plasma)

- sputtering (various tools) and evaporation (various tools)

- Centrotherm tube furnaces (thermal oxidation, LPCVD poly, LPCVD nitride)

- AML bonder/nanoimprint

For a complete list of equipment, see: http://www.micronova.fi/nanofabrication_centre-002/equipment/

Research group members:

Related content:

New funding to commercialise high-tech liquid-repelling coatings

New funding to get damage-resistant, liquid-repelling surfaces out of the laboratory and onto solar panels, skis, and more

To measure or not to measure? The basics of academic thinking provide students with problem-solving skills

Students of technology learn at an early stage of their studies that there may be various functional solutions to a single problem. Learning the skill to justify solutions scientifically is an integral part of the Master of Science in Technology education.

New method enables the recovery of trace platinum concentrations

Renewable energy and electric traffic will increase the need for critical metals. Even the smallest quantities of metal must be recovered.