Mineral Processing and Recycling

Our research areas:

-

Process engineering in service of the circular economy of raw materials

-

Green chemistry for mineral froth flotation

-

Physical separation technologies for recycling

Our current research activities include:

-

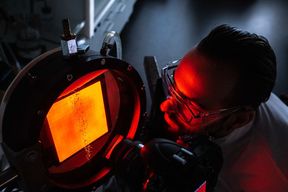

Fundamental understanding of interfacial phenomena in mineral froth flotation

-

Green chemical systems in mineral froth flotation

-

New physical separation operations for battery waste

-

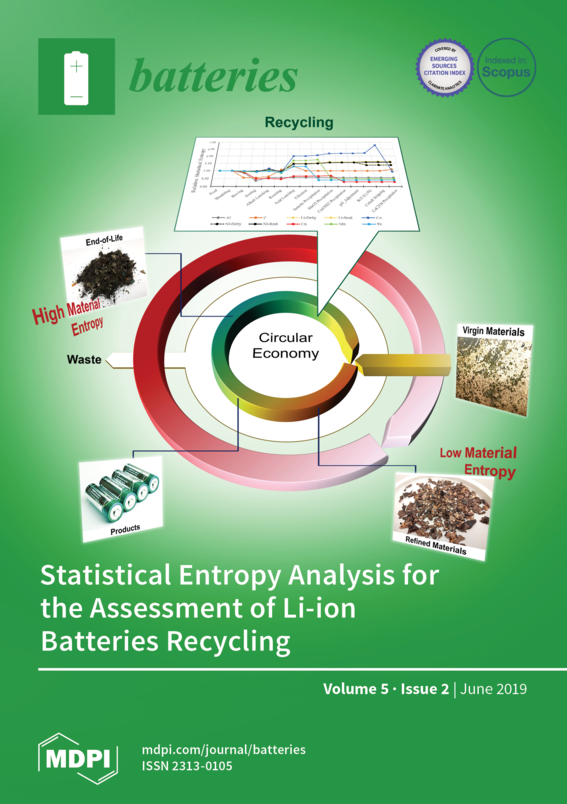

Statistical entropy analysis supported by process simulation as a parameter of materials circularity

The Research Group for Mineral Processing and Recycling is led by Prof. Rodrigo Serna. Our approach is to study the underlying phenomena responsible of the performance of mineral processing operations. Of particular interest is the study of the interfacial phenomena occurring during mineral enrichment, in order to gain a practical understanding on the correlation between adsorptive or surface chemical reactions and the macroscopic performance of the operations. Through the understanding of the phenomena involved, it may be possible to propose novel chemical systems that could further improve the efficiency of currently used enrichment operations, or even propose new processing methods altogether. The research group also counts with expertise in computational fluid dynamics with which alternative processing systems or new designs of mechanical components can be tested.

Our current research projects deal with the exploration of green chemicals for flotation and the quality and potential cross-contamination in water circuits. Our research group is also responsible for the courses related to mineral processing and recycling, including fundamentals, unit operations and plant design.

Research group members:

Join us!

- We are constantly looking for opportunities to improve the way in which we produce raw materials. We believe there is a better way for mining and recycling, both with new technologies and the active involvement of society. If you would like to know more about our group’s activities, please contact us (rodrigo.serna@aalto.fi).

- Are you already a student at Aalto looking for thesis topics or internships? Please enquire directly with us about opportunities (rodrigo.serna@aalto.fi)

- Interested on Doctoral studies in our team? Please check Aalto careers website for available positions

Related content:

New Academy Projects to be launched in September

New Academy Projects funded by the Academy of Finland involve expertise from all six Aalto schools

Ecofriendly chemicals can actually improve mineral processing

Nontoxic and biodegradable cellulose-based compound accelerates the mineral separation processes and reduces the use of other chemicals

Get to know us: Assistant professor Rodrigo Serna

Assistant professor Rodrigo Serna’s goal is to find new ways to produce sufficient raw materials for our modern society. Let’s hear more!

A joint laboratory of circular economy was opened in Otaniemi

The Geological Survey of Finland, VTT and Aalto University work together with industry to develop solutions for the needs of a carbon-neutral and resource-efficient society.

EIT-labelled course generates new talent and future leaders in the mining industry

The European Mining Course demonstrates a remarkable quality in terms of internationalization, educational innovation, entrepreneurship and societal impact.