Metallurgy

Our research areas:

-

Physicochemical fundamentals and modelling of metallurgical operations

-

Kinetics of metallurgical reactions especially in non-ferrous metals production

-

Recycling of e-scrap and energy storage materials in pyrometallurgical processes

The current research activities focus on physicochemical fundamentals and modelling of metallurgical operations, slags, mattes, ceramics and other high-temperature materials. Processes that benefit from this research include modern extractive and refining processes for ferrous and non-ferrous metals, casting and solidification as well as materials synthesis and behaviour at high temperatures. The main emphasis is on better understanding of metallurgical phenomena by combining experimental studies with computer simulation and modelling.

The Group’s strengths include expertise in thermodynamics, kinetics and transport phenomena as well as solid qualification in experimental research and material characterization.

Our research highlights:

-

Behavior of Battery Metals Lithium, Cobalt, Manganese and Lanthanum in Black Copper Smelting:

Recycling of metals from different waste streams must be increased in the near future for securing the availability of metals that are critical for high-tech applications, such as batteries for e-mobility. Black copper smelting is a flexible recycling route for many different types of scrap, including Waste Electrical and Electronic Equipment (WEEE) and some end-of-life energy storage materials. Fundamental thermodynamic data about the behavior of battery metals and the effect of slag additives is required for providing data necessary for process development, control, and optimization. The goal of our study is to investigate the suitability of black copper smelting process for recycling of battery metals lithium, cobalt, manganese, and lanthanum.

-

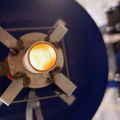

Computational Approaches for Studying Slag–MatteInteractions in the Flash Smelting Furnace(FSF) Settler:

Computational methods have become reliable tools in many disciplines for research andindustrial design. There are, however, an ever-increasing number of details waiting to be included in the models and software, including, e.g., chemical reactions and many physical phenomena, such asparticle and droplet behavior and their interactions. The dominant method for copper production,flash smelting, has been extensively investigated, but the settler part of the furnace containing moltenhigh temperature melts termed slag and matte, still lacks a computational modeling tool. In this paper,two commercial modeling software programs have been used for simulating slag–matte interactionsin the settler, the target being first to develop a robust computational fluid dynamics (CFD) modeland, second, to apply a new approach for molten droplet behavior in a continuum. The latter isbased on CFD coupled with the discrete element method (DEM), which was originally developedfor modeling solid particle–particle interactions and movement, and is applied here for individualdroplets for the first time.

-

Distribution Kinetics of Rare Earth Elements in Copper Smelting:

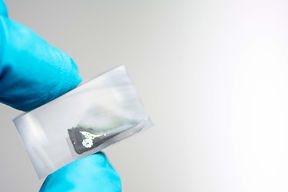

The use of rare earth elements (REEs) is increasing, mainly due to the growing demand for electric vehicles and new applications in green technology. This results in annual growth of the in-use REE stocks and the amount of End-of-Life (EoL) products containing REEs. REEs are considered critical elements by the EU, mainly because the rest of the world is dependent on China’s supply. Recycling of REEs can help alleviate the criticality of REEs, however, no REEs are currently functionally recycled. In this study, the time-dependent behavior of REEs in copper matte-slag system in primary copper smelting conditions was investigated experimentally at a laboratory scale.

Ari Jokilaakso“Metallurgy – Work that has a meaning”: metallurgy / metallurgists will save the world as the modern life is not possible without metals.

"Green” energy and electrification of vehicles need more metals (exponentially increasing amounts) and, therefore, metals production has to be developed for maximized yield and all metal products should be recycled back to metals production, which necessitates metallurgical basic research work.

- Ari Jokilaakso

Research group members

Related content:

Professor Ari Jokilaakso visited A-Studio on Monday, 15th March 2021 (external link)

The topic was about cobalt coming from the Republic of the Congo and the ethical challenges related to it. This clip starts at min. 23.25 (In Finnish).

Towards carbon-neutrality in metal production – new €18 million project to develop solutions for reducing CO2 emissions

Metal processing industry has the greatest greenhouse gas reduction potential of Finland's manufacturing industries. Joint project between companies and universities is a significant step towards carbon-neutral metal production.

Get to know us: Associate Professor Ari Jokilaakso

Circular economy is key.

How to get companies in the metal industry more employees and more students for the master’s degree programme?

‘The great thing about this cooperation is that everyone wins,’ said Ari Jokilaakso, Professor of metallurgy.

The sustainable use of metals is at the core of fighting climate change – It’s no use to substitute walking with electric scooters

Electric cars and electric scooters are not environmentally friendly options if they are used as an alternative to walking or cycling, for example. Different metals are constantly needed in increasing amounts for batteries, for example. The challenge is both ecological and social.

Half a million funding from Business Finland for the development of circular economy of metals

The funded sub-project of Aalto is part of SYMMET, which is searching for solutions to the increasing need for metallic materials.

Metallurgists are needed to fix the sustainability gap

Professor of Metallurgy Ari Jokilaakso’s researches the behaviour of chemical elements at high temperatures. He wants to give students a real understanding of chemical phenomena.

Metals needed for climate solutions – will what we have be enough?

Metal recovery and production processes using secondary raw materials must be developed and awareness of the need for recycling increased.