Wood Material Science

Our key research areas:

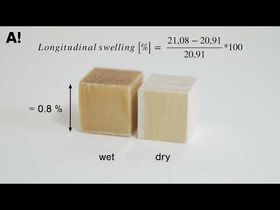

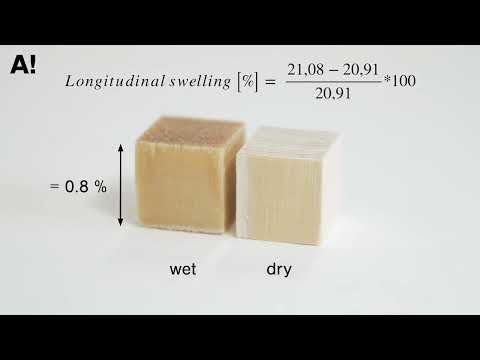

- Wood contains polar functional groups that attract water molecules from the surroundings. Absorbed water influences the performance of wood significantly (strength and stiffness, swelling, risk for deterioration by decay fungi). A better understanding of wood-water interactions will thus help in improving the performance of wood in the built environment.

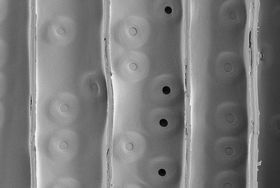

- Our group investigates the principles of how wood interacts with water molecules under different climatic conditions. We have developed several methods to study wood-water interactions in automated sorption balances. Besides traditional sorption isotherm measurements, we also specialize in quantifying accessible sorption sites in automated sorption balances using the deuterium exchange approach. We are also analyzing the link between moisture content changes and structural changes of the wood cell walls at the micro- and nanoscale using state-of-the art characterization tools such as confocal Raman microspectroscopy, or x-ray scattering techniques.

- As a natural material, wood and other cellulosic biomaterials often suffer from chemical heterogeneity in spatial dimensions. In our group, we are analyzing chemical heterogeneity at the macroscopic scale (several millimeters or more) and at the microscopic or cellular level (several micrometers or less). This is done by combining different chemical imaging tools, including confocal laser scanning microscopy, confocal Raman mapping and hyperspectral near infrared imaging. We are also focusing on applying chemometrics based on multivariate data analysis, which utilize the entire spectral range measured to find chemical differences in samples.

- We have used these chemical imaging methods in several research topics, ranging from the distribution of heartwood extractives in Scots pine wood to the process-related variation in modification degree in acetylated or impregnation-treated woods.

- Our native wood species typically do not have a sufficient durability in exterior applications and there are growing environmental concerns for the use of biocides for wood protection. An alternative approach is the modification with thermal, chemical, or other methods. The modified wood remains non-toxic during its service life and beyond and shows improved dimensional stability and decay resistance.

- Our group investigates different wood modification treatments, ranging from thermal modification methods and hygrothermal densification to chemical and impregnation-based modification methods or surface treatments using wood charring and biofilm coatings. We investigate the fundamental modes of action in modified woods and develop new strategies to modify our native wood species efficiently. Our laboratories offer a range of analytical tools to study anatomical and chemical changes of the cell wall as well as the resulting wood properties.

- Wood from sustainably managed forests is an excellent building material thanks to its high strength-to-weight ratio and its ability to store carbon over long periods. There is diversity of wooden products with different properties and applications, which range from solid wood products (i.e. cross-laminated timber and glued laminated timber) to veneer-based products (i.e. plywood and laminated veneer lumber) to particle- and fiber-based products (i.e. particle and fiber boards).

- Our group investigates the properties and behavior of wood-based materials, such as the distribution of heartwood extractives and its impact on biological durability, anti-bacterial effects of wood surfaces or the humidity-dependence of mechanical properties. We are also cooperating with industrial partners to optimize the manufacturing conditions, or to develop new processing concepts for a more efficient use of wood in the built environment. We have a strong expertise in the evaluating the wood bondability with different adhesive systems or the design of wood products for novel applications.

- Mycelium composites are a growing research area in the built environment due to their low cost and ability to use waste or recycled raw materials. These composites utilise natural fungal growth as a low-energy method to upcycle forest and agricultural side-products and wastes into more sustainable alternatives to energy-intensive synthetic construction materials.

- Mycelium composites can have tailored materials properties depending on their composition and manufacturing process. They can be used for example as building components and as packaging materials.

See videos about our research

For example:

- PerfectWood: Durable wood materials in future products, funded by Business Finland + 7 companies (Aalto + VTT)

- 1.1.2024 - 31.12.2026

- Waterwood: Water vapour soprption behaviour of wood under load, funded by Academy of Finland

- Modification of wood veneer (EU/ERDF, 2016-2018)

- Lasting wooden facades with surface charring - SurfaceMod (PintaMod; EU/ERDF, 2017-2018)

- Colloidal lignin adhesives and coatings - COLIAD (Tekes 2016-2018)

- Developing the ThermoWood process and products (EU/ERDF 2015-2017)

- Recycling possibilities for wooden packaging waste and wood working industry by-products - RecycledWood (KiertoPuu; EU/ERDF 2019-2020)

- Wood modification using pressurized hot water - HOTWOOD (Academy of Finland, 2017-2021)

- Interactions of wood and water in the nanoscale - WooD2O (AoF 2018-2021)

Wood science teaching

We offer teaching related to wood material science, wood products and processes and life cycle analysis of wood products to a wide audience, including students from different fields in Aalto, students from other universities, as well as, life-wide-learners.

Find out more about our courses here.

To support learning we keep on developing new learning materials and videos, see examples presented below.

Even more videos can be found from this Youtube-channel:

Join us!

We are continuously looking for talented researchers (Aalto students, MSc thesis workers, doctoral students and postdocs).

For further information, contact Prof. Lauri Rautkari (firstname.lastname@aalto.fi)

Research group members:

Emil Jansson

Pasi Herranen

Katja Vahtikari

Faksawat Poohphajai

Callum Hill

Related content:

New Academy Projects to be launched in September

New Academy Projects funded by the Academy of Finland involve expertise from all six Aalto schools

Associate Professor Lauri Rautkari appointed as Deputy Head of the Department at Bio2

Associate Professor Lauri Rautkari has been appointed Deputy Head of the Department of Bioproducts and Biosystems at the School of Chemical Engineering as of 1.8.2023.

Nearly 20 million euros for research

The Academy of Finland funding brings nine new posts as Academy Research Fellow, 15 new Postdoctoral Researchers and 24 new Academy Projects to Aalto University.

Anything but an ordinary greenhouse

A wood-structured windowless greenhouse consumes only half as much energy as a traditional glass greenhouse. In addition to producing food, Pasi Herranen’s invention could generate electricity and excess heat in the future.

Wood Wonders exhibition showcases climate-friendly building concepts

If all the buildings constructed in Finland each year were made of wood, the amount of wood needed for their construction would grow back in ten hours.

New minor: Aalto Wood

For students in any field interested in wood!

Wood science teaching

Wood science and technology is taught by the Department of Bioproducts and Biosystems.

Investments in wood competence

Significant sum of donations of 700 000 euros enables high-quality wood science teaching with wider availability.