Printed Perotech

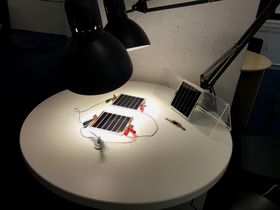

Printed perotech offers a route to low-cost architecturally interesting solar panels.

If we want the abundant, emissions-free electricity from the sun to be widespread and easy to use, then solar panels need to be cheap and easy to make. Currently available solar panels need large factories with highly controlled atmospheres and specialist equipment that cost billions of dollars each to build.

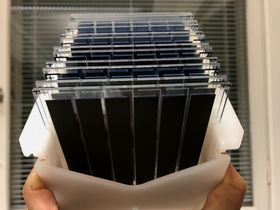

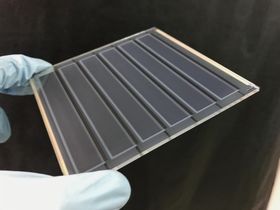

Printed perotech looks to overcome this by using new materials that can work like a solar panel, but can be produced by simple printing processes. Developed at Aalto university by Dr Syed Ghufran Hashmi, Printed perotech can produce functioning solar panels on commercially available printers in a regular manufacturing laboratory.

This is a huge step away from traditional solar panels, which are made using large pieces of pure silicon. Silicon solar panels are expensive, difficult to adapt to different patterns, and tend to dominate the appearances of the buildings they power.

Printed perotech solar panels can be tailored to match the architectural style of the buildings they are powering. The printed perotech team plan to provide large, glass-covered structures like shopping malls, airports, and office blocks with solar energy.

They are now working on a proof of concept to show that their technology is scalable and ready for mass production in industry. The team has received 0,76 million euros in funding for their development from Business Finland and Aalto University for 18 months to finalise their technology into a viable market product. Dr Hashmi explains: “our technology makes it possible for the first time to integrate desirable design for architectural integration, inexpensiveness and efficiency for proper energy harvesting.”