Smart crane receives open development environment

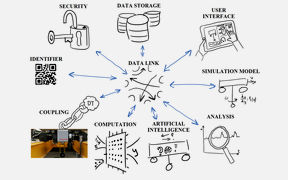

In 2017, Konecranes donated an industrial crane to Aalto University. The crane was given the name Ilmatar and has been utilised in various course assignments and student projects. In addition, researchers and partners have developed, as part of the DigiTwin project, a digital twin for the crane – a virtual environment that can be used both for conceptual work and for practical machine design and maintenance needs.

Some of the digital infrastructure formed for the crane has been made public. An open development environment has also been built using freely available resources.

Ilmatar Open Innovation Environment, Ilmatar OIE, was officially opened for use on 22 November.

‘The idea is that other companies too will be able to test how their products and services work with the crane – first in a virtual environment and then by verifying the functionality of their solutions using the university's physical crane,’ explains Juuso Autiosalo, Project Manager for the DigiTwin project.

‘The open factory ecosystem built around Ilmatar and its digital twin is a very interesting project for Konecranes. In the future, equipment manufactured by Konecranes will increasingly be connected to design, process control and factory systems. With the help of the digital twin, the suitability and functioning of the device can be verified and improved at different stages of the device's life cycle, starting from the customer's factory design,’ explains Timo Harjunen, Director of IoT and Digital Platform Development at Konecranes.

From crane to robot

Industrial cranes like Ilmatar are needed in almost all factories around the world. According to Autiosalo, the development environment can be utilised by a wide range of companies, from algorithm makers to developers of supplementary devices.

‘In the future, the crane can become yet another robot, and the development of the required software will be considerably easier thanks to the digital twin.’

On the industrial Internet, devices and systems are connected to the network to form intelligent entities. However, until now the data related to a specific device has been difficult to access and, for example, modifying the settings of the device has required direct communication with the device itself, which is not possible when the device is out of the reach of data connections.

‘The goal is that all communication related to a physical device is done through a digital twin, in which case all data can be found in the same place and if, for example, the electricity is cut off from the device itself, this does not hinder the updating process. The digital twin takes care of the device, and people's everyday life becomes easier,’ explains Juuso Autiosalo.

You can learn about the opportunities offered by the Ilmatar development environment at https://aalto.fi/ilmatar, and by registering you can access the digital resources of the development environment. For safety reasons, the implementation of the tests on a physical crane requires user training. In addition, new research projects can be initiated as and when they are needed.

Aalto University is also involved in the MACHINAIDE project, which is examining the requirements for cooperation between digital twins made for different manufacturers' devices and the efficient combination of the information obtained from them. MACHINAIDE is an international EUREKA ITEA3 project with industrial partners from different fields and its total budget is EUR 9 million.

More information:

Doctoral Candidate, DigiTwin Project Manager Juuso Autiosalo

tel. +358 (0)50 340 9550

juuso.autiosalo@aalto.fi

Aalto University invests in international cooperation in digital twin research

The MACHINAIDE project explores the prerequisites for collaboration between digital twin devices made by various manufacturers and for the efficient combination of information from them.

Read more news

Kielibuusti Project 2025–2028 Supports International Students and Staff at Aalto University

The Kielibuusti enhances opportunities for international students and staff to learn and use the Finnish language, and it supports the multilingual working practices within the Aalto community.

Design strengthens industrial competitiveness – human-centered factory work at the core

Factory work is undergoing a transformation: new technologies and artificial intelligence are changing the content and roles of work. Aalto University’s Department of Design is studying this change from a human-centered perspective in the HiFive project.

Learning to slow down: cold-water swimming benefits explored in new study

Swimming in cold water offers a temporal slowdown, promoting stress management and mental clarity that lingers long after the experience, says research from Finland.