Electronics and Nanotechnology, Master of Science (Technology)

By developing modern hardware technology, electronics and nanotechnology experts play a key role in shaping the future.

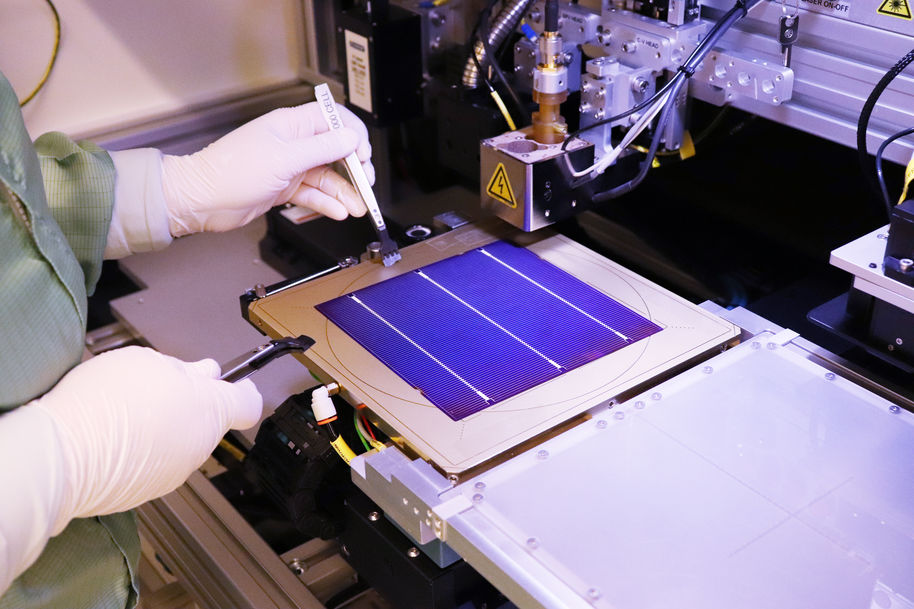

How does a solar cell work and what are the problems you need to take care of in order to get a solar cell work efficiently? This was the topic of the very first lab session of the Micronova Laboratory course. The students studied a wafer and a finished cell and were given the task to figure out what had caused the differences between the two. Hints for this puzzle were given on a cleanroom tour on which methods and equipment used in the process of making solar cells were presented.

“Now that's cool!" On the second lab session students were given an introduction to the scanning electron microscope. They got hands-on practice with the tool by imaging a sample of compound semiconductor nanowires. These crystalline structures typically have the length of some tens of micrometers – that's one millionth of a metre – so they are tiny! Due to their useful optical, electrical, and mechanical properties they have a vast range of applications in several fields including photovoltaics, optoelectronics, photonics, and electronics.

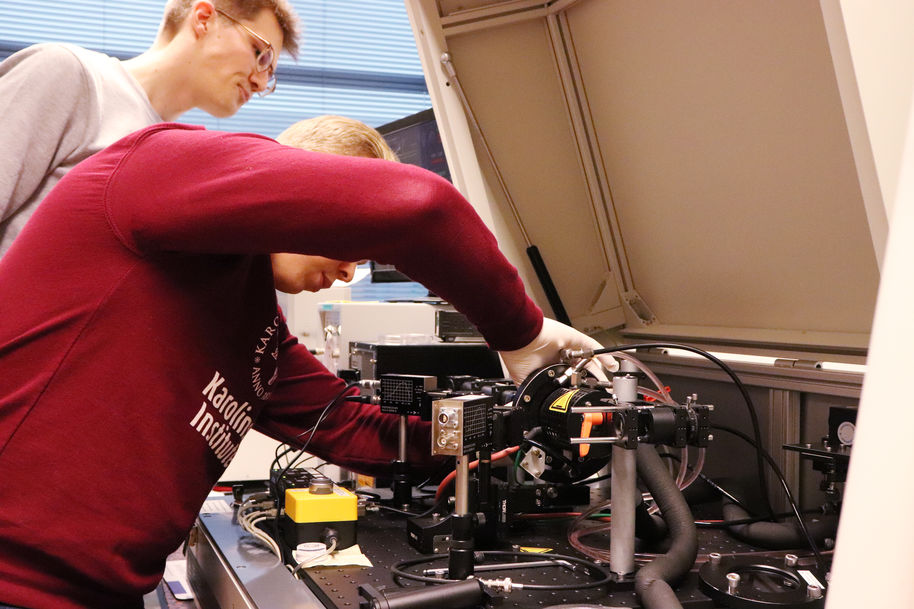

The third lab session was about thermal conductivity. By engineering the thermal properties in nanomaterials used in modern micro- and nanoelectronics, it’s possible to achieve big improvements in power consumption and energy efficiency in, for example, mobile phones. The students familiarised themselves with the effects of nanostructuring on material thermal properties and got to use an optical pump-probe thermoreflectance setup.

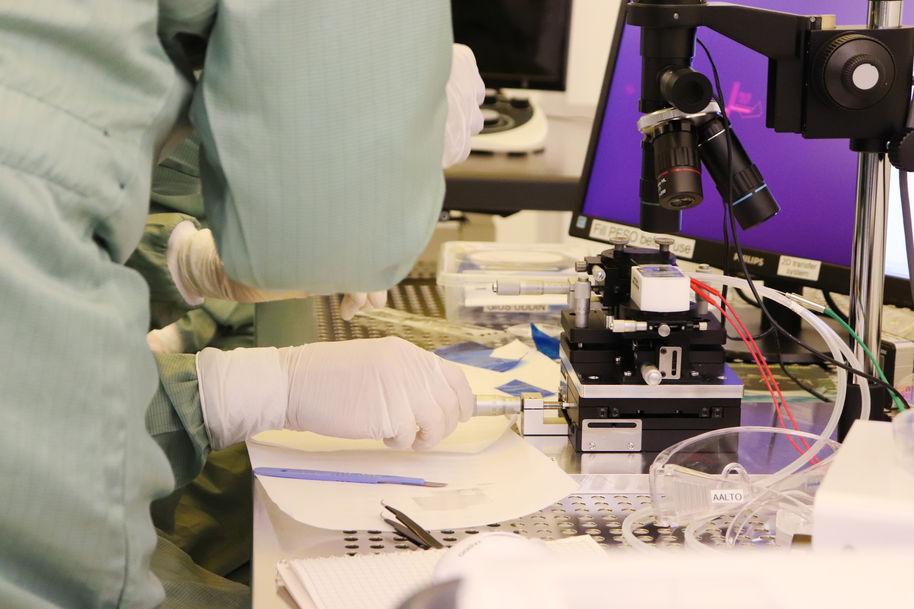

Photonics – the science of light – was the topic of the fourth lab session. The students got to try a method called ‘dry-transfer’: they obtained atomically thin flakes of a two-dimensional material called molybdenum disulfide and transferred a flake onto a silicon chip to make devices like transistors out of it. 2D layered materials have unique mechanical and optoelectronic properties that can be combined in a single device such as flexible displays.

A human hair is about 50 000 nanometers thick. But how can you determine the thickness of a 10–1000 nanometer thin film? On the last lab session students learned about X-ray reflectometry – an analytical technique for investigating thin-layered structures, surfaces and interfaces using the effect of total external reflection of X-rays. First, a hafnium oxide coating was grown on a silicon substrate thin film using atomic layer deposition. As the density difference of the thin film and the substrate causes interference in the low angle X-ray reflection, the students were able to determine the film’s thickness, density and roughness.

The Micronova Laboratory course is part of the Master's Programme in Electronics and Nanotechnology.

By developing modern hardware technology, electronics and nanotechnology experts play a key role in shaping the future.