Rotor geometry measurement and manufacturing methods

Research relating to rotor geometry measurement and manufacturing methods has been performed in the ARotor laboratory for over two decades.

Multi-probe error separation methods can be used to accurately determine a roundness profile of a rotating workpiece, when there is unrepeatable center point motion. Such conditions are found for example in large flexible rotors such as paper machine rolls, where the mass and thickness combined with the bearing errors can cause a center point movement during the measurement.

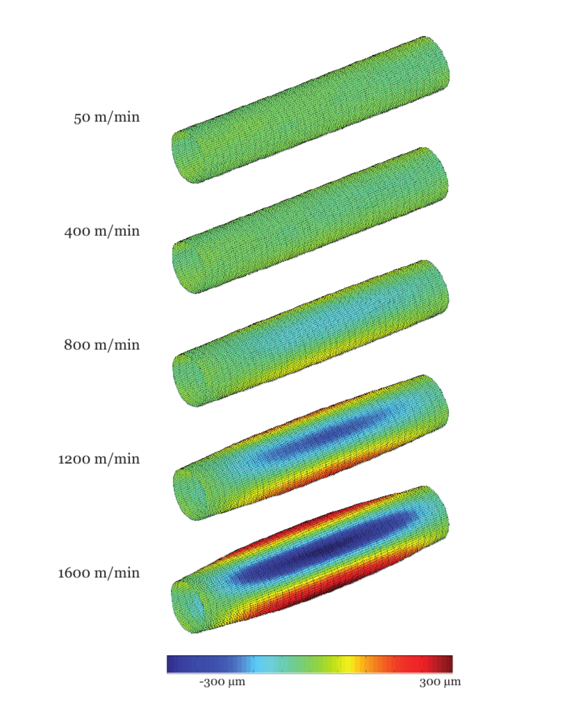

Applying multi-probe roundness methods for rotors measured in their operating speed and on their own bearings enables measurement and manufacturing for operating conditions. The aim is to simulate external conditions to produce rotor system behaviour is close to what it will be during operation.

The methods have been applied to industrial applications, such as 3D roll grinding, where the dynamic change of the roundness profile of the roll cross sections is compensated for by grinding.