Tampere University

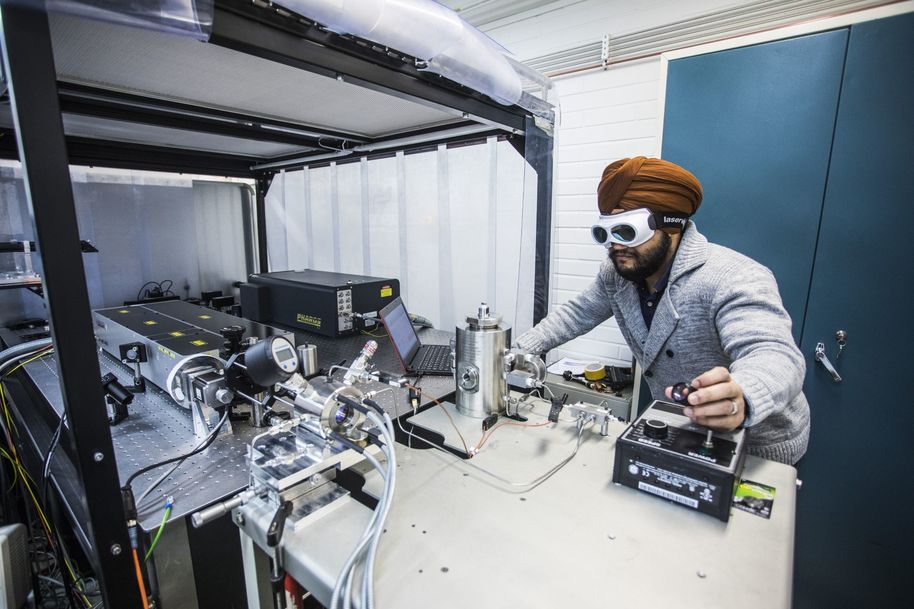

In the NextGenBat project, Tampere University (TAU) will implement its know-how on ceramic materials processing and pulsed laser deposition (PLD) coating technology to sensitive battery materials.

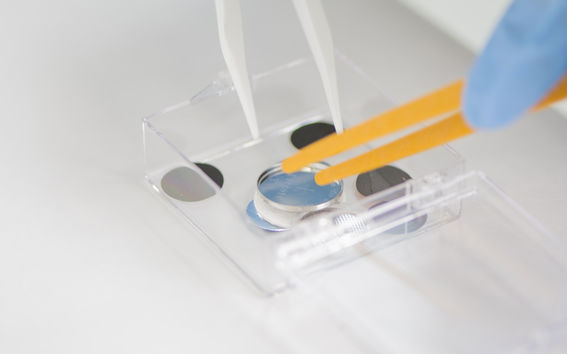

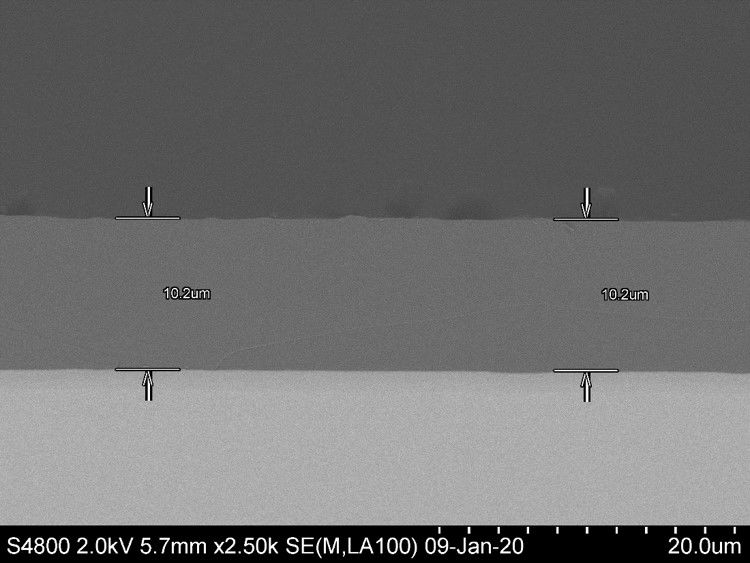

The TAU Ceramic materials research group investigates materials related to the PLD process, e.g., raw material development, target processing and post treatments of coatings. The target materials and structures of PLD are in a focal role for developing reliable and effective components for lithium-ion batteries.

About Tampere University

Multidisciplinary, foundation-based Tampere University is Finland’s second-largest university. TAU conducts scientific research in technology, health and society and provides the highest education within these fields. Tampere University Foundation that operates as Tampere University is also the majority shareholder of Tampere University of Applied Sciences. This new higher education community in Tampere consists of 30,000 students, 330 professors, and 4,400 employees.

Materials Science and Environmental Engineering (MSEE) is one of the units under Faculty of Engineering and Natural Sciences. MSEE has three research fields: Engineering Materials Science (EMS), Chemistry and Advanced Materials, and Bio and Circular Economy. The Engineering Materials Science research activities cover all material groups, i.e., metals, ceramics, polymers, and composites and technologies like surface engineering, paper and packaging, and tribology.

The Ceramic Materials research group, headed by prof. Erkki Levänen, focuses on research of green processing and properties of functional and engineering ceramics. The group has expertise on and access to equipment for whole manufacturing steps for ceramic materials, from powder synthesis and processing to shape forming and sintering. Current interlinked research highlights are; green scCO2 assisted laser processing of ceramics, inorganic circular economy, ceramics via PLD; plastic deformation of thin film alumina and 3D manufacturing of functional ceramic materials and structures.