Chemical engineering

The research methodology is based on natural sciences and mechanistic modelling of chemical processes. The research aims at developing methodology and tools that allow fast and reliable development and scale-up of new industrial chemical processes. Teaching in Chemical engineering aims at development of generic skills and fundamental understanding of chemical processes. This understanding can be applied in a wide variety of chemical technology fields and practical applications.

Annually about 2 doctoral students finish their doctoral thesis and about 10 master students finish their master thesis.

Our research areas:

-

Modeling of multiphase processes

-

Phase equilibria

-

Microprocess technology

1. Modeling of multiphase processes:

Modeling of thermodynamics, transport phenomena, and multiphase chemical processes. The aim in this focus area is to combine fundamental models describing molecular scale kinetics into unified integrated process modeling tools with high predictive power. These tools can significantly speed up traditional process development and design.

Our group has expertise in modeling various multiphase chemical processes, such as separation processes and multiphase reactors. Our core competence in that field is to combine mass transfer, population balances, thermodynamics, fluid flow and reaction models. Our expertise covers both chemical engineering applications and numerical methods for solving the models.

2. Phase equilibria:

In the field of phase equilibria, we have extensive laboratory facilities for measuring phase equilibria and thermodynamic properties. Our expertise covers vapor-liquid equilibria and gas solubility measurements extending to very high temperatures and pressures with applications ranging from traditional oil refining to novel biorefineries and CO2 mitigation. In addition, we have expertise in measuring liquid-liquid equilibria for solvent extraction and solid-liquid equilibria.

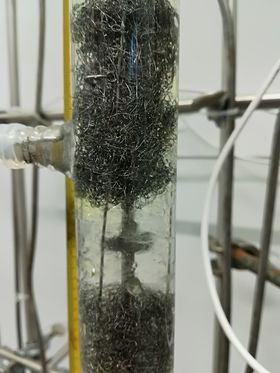

3. Microprocess technology:

We have also expertise in microprocess technology, mainly for developing and designing micro/milli scale distillation units and combining miniaturized units into continuous pilot units.

The technology is also applied in research of process intensification with integrated miniaturized chemical process plants.

Ongoing projects:

- Phase Equilibria for Bio-refineries (PEQBIO)

- Crystallization - FLUKI

- Academy Research Fellow Project: Process development intensification by utilization of a new generation of Micro-plants

- Physical Properties and Phase Equilibria Measurements for Pyrolysis Oil Components

- Phase Stability Calculation and Equilibrium Measurements for Biorefinery

- Fubio Joint Research 2 / Ionic Liquids

- Fubio Joint Research 2 / Modelling of Hot Water Extraction

- Products from dissolved cellulose / Modelling of viscose process

- CLEEN- Carbon Capture and Storage

Ville AlopaeusOur work combines high quality academic work into powerful tools that can be used in industrial process development and scale-up.

Research group members:

Related content:

Environmental technology is a way of thinking

Green ideas should penetrate both education and industry says Ville Alopaeus, awarded with Tapani Järvinen Environmental Technology Fund grant.