Biobased Materials Technology

Our research areas:

-

Pulp fiber structure and modification

-

Carbon materials and energy storage

-

Nanocellulose films

The BIOMAT team leverages the inherent possibilities of cellulosic fibers as building blocks for new sustainable products. Production of nanocellulose films, pulp dissolution, and porous carbon materials are current themes. We specialize in pore structure measurements and cellulose/water interactions.

Research themes:

1. Nanomaterial applications:

The BIOMAT team is developing nanomaterial applications for various fiber products. Especially, we are focused on technologies which have potentially large scale applications at an attractive cost structure.

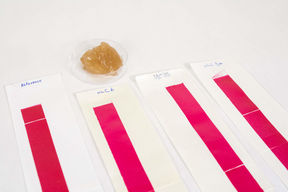

NFC/MFC and nanopapers production

"Nanopapers" refers to paper grades where nanocellulose is a major structural component. Nanopapers have very different, and often superior properties than traditional grades of paper. We are working on nanocellulose production, suspension processing and nanopaper forming and dewatering issues.

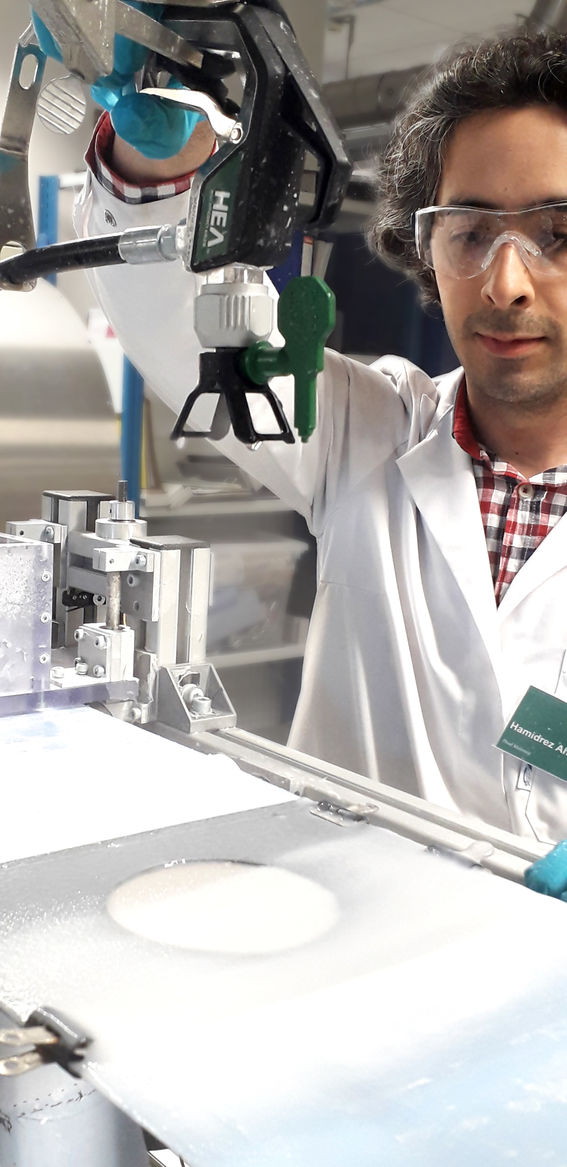

Spray, roll, and airlaid forming methods

All-carbon films

We are developing graphene/nanocellulose composites and all-carbon films for various electrical applications.

2. Porous cellulosic materials:

The BIOMAT team is working on porous cellulosic materials. Lignocellulosic fibers and assemblies of nanocelluloses and other forms of cellulose have a fascinating pore structure that can be exploited in a number of product applications. This includes; liquid and gas phase absorbents, hygienic products and phase change composites for construction applications. In the world of porous materials, lignocellulosics are today very under represented. This work includes the development of cutting-edge techniques for measuring fiber, nanofiber and cellulose composite pore structure. We are also working on ways to modulate and stabilize the porosity of cellulosic materials and composites.

Porous nanopapers

In this area of research we are developing methods for producing high surface area and highly porous papers from nanocellulose-based furnishes.

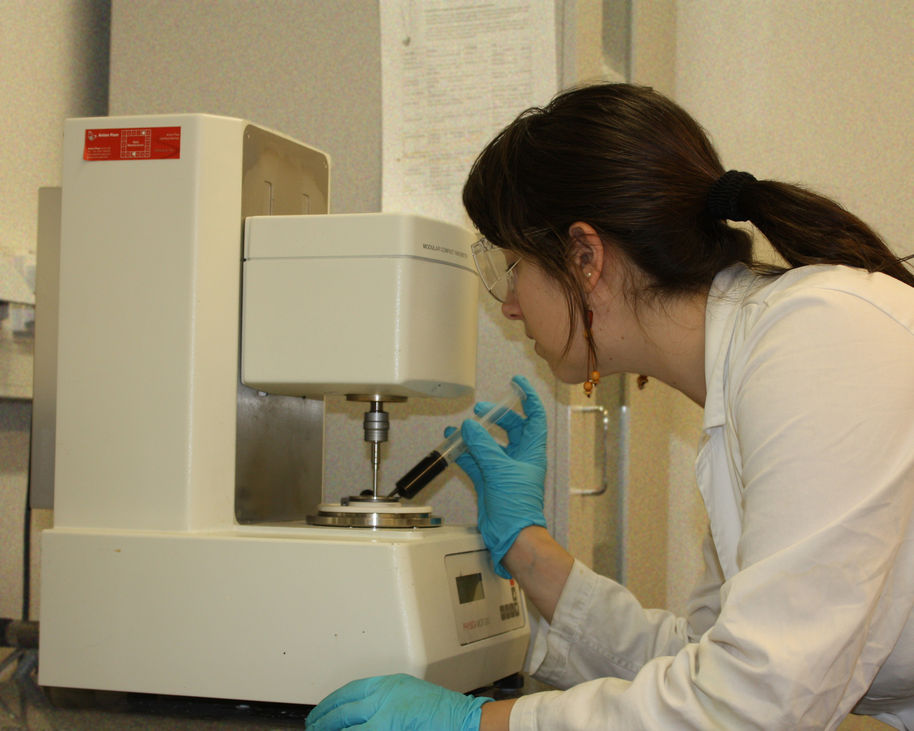

Novel thermoporosimetry techniques

New approaches to thermoporosimetry are being developed including techniques based on unusual transformations of salts and solvents in confined geometries.

3. Dissolution of pulp fibers:

Assessment and enhancement of pulp reactivity

This study investigates the behavior of pulp under direct dissolution. Pulp reactivity is indirectly assessed monitoring the rheological behavior of pulp suspensions while the fibers are dissolving. The goal is to provide a deeper understanding of which pulp features affect pulp reactivity and to use this knowledge to develop different activation treatments.

Academic and Industrial Collaborations:

We have a multidisciplinary international team that works closely with industrial partners on topics that support the renewal of the forest products industry. Our work is dedicated to advancement of sustainable raw materials and products in areas where our partners see possibilities for value creation.

New collaborations with:

- Coimbra University

- UBI University (Portugal)

- Karlstad University

New projects with:

- Stora Enso

- UPM Kymmene

- Navigator Company

Research group members:

Recent graduates:

Functional Properties of Mechanically Exfoliated Graphene (http://www.urn.fi/URN:ISBN:978-952-60-8863-1)