Study: Internal combustion engine can achieve zero-emission combustion and double efficiency

The HyMar project, conducted at Aalto University and the University of Turku, has produced results in a short time that could revolutionize the entire field of combustion engine technology.

The idea is to replace the air used in combustion, i.e. a nitrogen–oxygen mixture, with an argon–oxygen mixture.

'This could be a true game changer for combustion engines, as the exceptional thermodynamic properties of argon fundamentally alter the combustion process,' says Ville Vuorinen, Associate Professor of Energy Technology at Aalto University.

If the concept proves viable, its climate and energy-efficiency benefits would be unprecedented. In an argon cycle, the engine produces no nitrogen oxides (NOx), which are among the most harmful climate-forcing and health-impact pollutants. And when green hydrogen is used as fuel, the engine can operate with no carbon emissions at all.

At the same time, fuel consumption can drop by as much as half without sacrificing power output. Such high efficiency could accelerate the market uptake of cleaner fuels by helping offset their initially higher production costs compared to fossil fuels.

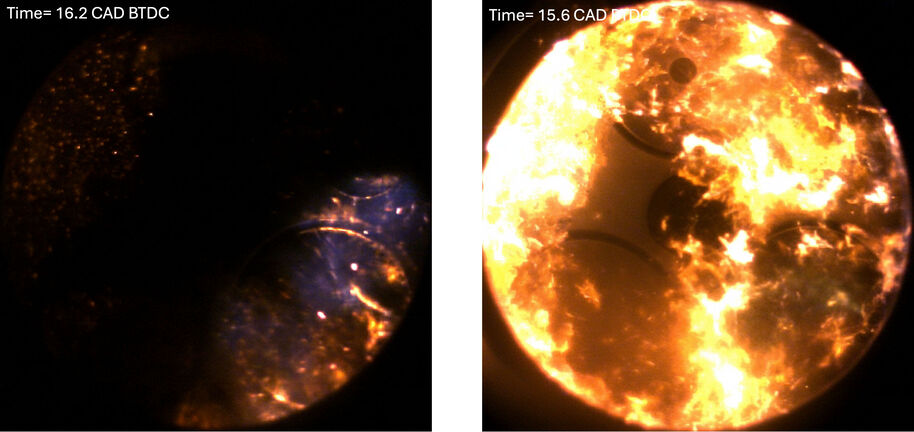

A key breakthrough in the project so far has been capturing combustion phenomena inside an optical engine. Vuorinen describes the visual observations as striking.

'To our knowledge, we are the first research group in the world to capture, using an optical engine, what actually happens during the combustion of hydrogen, argon and oxygen. Measurements supporting our theoretical predictions also clearly show that the concept is technically feasible,' Vuorinen says.

New possibilities for green hydrogen

Green hydrogen is widely considered a fuel of the future, but even hydrogen is not entirely emission-free. Hydrogen combustion requires air, which consists mostly of nitrogen. At high temperatures, nitrogen reacts with oxygen and forms NOx emissions. The same challenge affects methane combustion, for example in LNG vessels and gas turbines.

The key to zero-emission combustion is argon, which replaces nitrogen in the process.

'Another unique property of argon is that it allows much higher compression temperatures and pressures than ordinary air. This significantly increases engine efficiency because a larger share of the fuel’s energy is converted into useful work rather than lost as heat,' Vuorinen explains.

A conventional gasoline engine typically has an efficiency of 20–30 percent, and a diesel engine 30–40 percent. In an argon cycle, efficiency could rise even up to 70-80 percent.

According to Vuorinen, this opens the door for new clean fuels.

'Hydrogen does not ignite as easily as diesel, and ammonia ignites rather poorly. The argon cycle could give these fuels ‘diesel-like’ properties, improving their ignition and combustion behaviour.'

Cameras capture the flame

HyMar project, funded by the Research Council of Finland, aims to yield new insight on hydrogen and methane combustion phenomena in argon-cycle engines. At Aalto, Vuorinen’s computational fluid dynamics and combustion physics group oversees the experimental work in collaboration with Staff Scientist Cheng Qiang. Researchers at the University of Turku complement the project with additional modelling expertise.

Aalto hosts a highly advanced combustion research facility.

'With it, we can image and measure argon combustion in great detail. The optical engine’s quartz piston window enables us to record ignition and flame behaviour inside the cylinder using high-speed cameras,' Qiang explains.

Until now, argon combustion has been studied only in simple combustion chambers or sealed engines, and even then very limitedly.

'Our next step is to investigate in more detail how hydrogen, argon and oxygen behave under engine-like conditions. The goal is to deepen the scientific understanding and move the argon-cycle concept closer to practical implementation,' Qiang says.

Applications from power plants to maritime transport

According to the researchers, the argon-cycle engine is particularly suitable for applications requiring very high efficiency, zero emissions and the use of green hydrogen as fuel.

'The engine is ideal for industrial power plants, hydrogen hubs and chemical facilities that aim for fully emission-free on-site energy production. It is also a promising solution for maritime transport,' Qiang says.

Vuorinen also sees broad potential.

'I see opportunities for many types of fuels. More than 80 percent of global energy is still produced through combustion processes. The argon cycle offers a pathway to eliminating NOx emissions entirely. It is deeply motivating to continue this research,' he concludes.

Text: Marjukka Puolakka

Image below: Qiang Cheng ja Joakim Kapp

More information

Read more news

Soil Laboratory Exhibition – Exploring the Dialogue Between Human and the Earth in Utsjoki

Soil Laboratory explores the relationship between humans and the earth as a living landscape through ceramic practices in Utsjoki.

The Finnish Cultural Foundation awarded grants for science and art

A total of 15 individuals or groups from Aalto University received grants

Environmental Structure of the Year 2025 Award goes to Kalasatama-Pasila tramway

The award is given in recognition of meritorious design and implementation of the built environment. Experts from Aalto University developed sustainability solutions for the project.