Results in review: DiCtion is digitalising construction workflows

The seminar summarised the insights from DiCtion, Aalto University’s two-and-a-half-year research project. The changes that the research teams have envisioned – when implemented – carry the potential to make a considerable impact on on-site productivity.

The seminar took place on 23 September 2019. Here are some picks from the presentations.

The general workflow data model

One of the critical challenges facing those operating in or researching the construction sector is that day-to-day work rarely involves a sequence of clean-cut activities – as is commonly the case in industrial manufacturing. Instead, workflows often happen simultaneously, often in the same spaces and potentially overlapping or disturbing each other. This creates a communication issue where companies and their on-site crews are ‘not up to date’ on what’s happening next and can run the risk of being derailed by conflicting schedules.

In this case, digital information management tools – coupled with real-time data from the construction site – can quickly mitigate the problem. However, a major challenge in the development of these tools is that there is no generally accepted data model for construction workflow management.

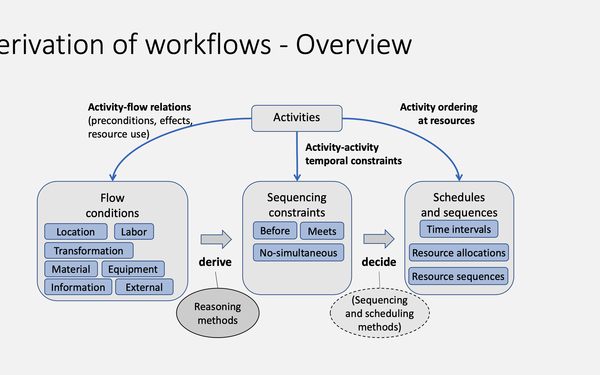

Dr. Seppo Törmä presented his and Yuan Zheng’s research that proposes a novel data model to address this issue. Their design details every piece of information needed to describe, plan and manage on-site construction workflows. Included are data definitions for activities; their relations to workflows, sequencing constraints and schedules; and sequences of activities. The data required for workflow management can also come from a range of sources: BIMs, on-site sensors and construction management tools.

Törmä also pointed out that their multi-faceted model must also be able to manage workspace requirements for different activities. This was visualised by using an example of a room with three partially overlapping activities: a door installation, a floor covering, and window installation. These tasks required a set workspace and could take place in an allocated sequence.

Decentralised space planning

Törmä’s presentation ignited a lively discussion concerning the use of location breakdown structures (LBS). It quickly became evident that following a centralised, hierarchical and simplified approach did not mesh at all with detailed workflow planning. The workspace technique tested in DiCtion seemed to serve practical purposes much better.

This was complemented by Alaa Al Barazi’s research that addressed the shortcomings of current planning methods. His work conceptualised a decentralised, flexible, and dynamic space-planning system based on workspaces and situational awareness.

Al Barazi made clear why his research topic was truly timely and relevant with references to studies that illustrate how reality rarely meets proposals made in typical lookahead plans. Plans with a one-week lookahead window were only 47 % accurate. When this was expanded to two months, only 5 % of the tasks were on time. Finally, none of the three-month plan’s tasks hit the mark; they were either delayed (49 %) or took place too early (51 %).

The research is still at an early stage, but Al Barazi was able to illustrate his idea with a space planner demo application. This featured a floor plan of an apartment with defined workspaces and HVAC and drywall workers moving around, tracked by IoT beacons.

The simulation visually displayed who was on the premises, if they were in their intended workspace and their duration of stay. The demo gave a glimpse into the potential future of situation-aware space planning – highlighting new opportunities to organise and efficiently monitor work to increase on-site productivity.

Understanding workers' needs

Christopher Görsch presented his project, which aimed to better understand construction workers' on-site processes. Embodied knowledge is often understood as an invaluable asset when securing a competitive advantage, but on-site workers are still a broadly untapped resource when it comes to developing productivity in the industry.

Görsch’s project looks to scrutinise how information in plans and schedules supports on-site decision making and worker performance. He also aims to explore future opportunities to improve situational awareness on construction sites.

As a research method, Görsch has chosen to use surveys. He described his survey process and provided the audience with links to English and Finnish versions of the survey documentation. The material is extensive, taking about 25 minutes to complete. The goal is to get up to 1 000 respondents to participate.

Managing the prefabrication supply chain

Prefabrication is a globally rising trend in construction. Dr. Markku Kiviniemi’s presentation shed additional light on how to better integrate design and construction with prefabrication and eliminate process waste. To do this, the research team interviewed representatives from Ruukki and Consolis Parma to map out their sales, project management, fabrication and logistics processes in construction projects.

The researchers have already begun to come up with new proposals detailing how to digitalise prefab supply chain management. For example, the team suggested that the general contractor’s master schedule should be presented as structural data. This could then be easily linked to manufacturers’ ERP systems and BIMs.

In interviews, fabricators indicated that they’d be keen to receive updates on the design progress. Obtaining accurate data about installation sequences ahead of time would then help optimise production planning and logistics. The use of situational awareness and quality-related data from construction sites would also work to streamline the overall process and meaningfully save on quality costs.

Professor Antti Peltokorpi then gave a summary of another task in the same research work package. This dealt with "kitting," or the use of packages of re-collected materials and components that are delivered on schedule to the workface. Kitting potentially stands to save time for employees as they don’t have to do any collection tasks themselves. The researchers are currently considering how the kits can be presented in the construction data model and how they tie into the logistics data process.

Case studies provide data

Ana Reinbold gave an overview of a range of case studies, an essential part of DiCtion. They include – among others – data collection from construction sites, smart drawings, video tracking studies, visual management development and surveys.

Professor Olli Seppänen urged attendees to come up with an ultimate case study. This would be a construction project that provided a complete set of BIM models, used all the possible sensors and image tracking, utilised comprehensive digital schedules, provided logistics data and so on. The data would then populate the whole ontology and showcase the value of DiCtion.

DiCtion will continue until June 2020. In this time, it will certainly produce more exciting insights and provide concrete solutions to the construction industry’s most pressing productivity challenges.

Read more news

Apply Now: Unite! Visiting Professorships at TU Graz

TU Graz, Austria, invites experienced postdoctoral researchers to apply for two fully funded visiting professorships. The deadline for expressions of interest is 20 February 2026, and the positions will begin on 1 October 2026.

Hanaholmen’s 50th anniversary exhibition lives on online – making the history of Finnish–Swedish cooperation accessible worldwide

MeMo Institute at Aalto University has produced a virtual 3D version of the anniversary exhibition of Hanaholmen.Soil Laboratory Exhibition – Exploring the Dialogue Between Human and the Earth in Utsjoki

Soil Laboratory explores the relationship between humans and the earth as a living landscape through ceramic practices in Utsjoki.