Real-time Data Helps Improve Construction Productivity

The research in that we discuss is part of the DiCtion - Digitalizing Construction Workflows project led by Aalto University.

Can you tell us a bit about yourself and your PhD topic?

I'm originally from China. I took my master’s degree at KTH in Sweden where my major was real estate and construction management. I moved to Finland from Sweden about three years ago.

My PhD topic is Using Real Time Tracking System to Improve Production Control in Construction. I’m in my last year of my PhD and also looking for job opportunities in relevant companies.

Why did you choose that particular topic?

I was interested to jump out of the previous study field, which is real estate, to another - construction management. I believe that there is a lot to improve in the field of construction management and there are potentially very good opportunities for a career path in that sector. I'm also very interested to use live data to support and improve construction and reveal real life problems in the industry.

What is the problem that you're aiming to solve and why is worth solving?

I think it's a commonly known issue that there’s a lot of waste in construction. But the industry hasn’t really done anything very concrete to solve it. There are also issues with the reliability of workflows. And that leads to the source of a big amount of a loss in terms of productivity.

I’ve reviewed several studies in this field and found out that the value adding ratio on construction sites is usually quite low. For example, workers’ presence on the site ranges from 25 percent to 67 percent.

In my research, I’m applying real time tracking systems. We’ve been developing an automated detection of task progresses. Also, as a part of my PhD, I develop KPIs to evaluate, for example, the relationship between production and the presence of the workers on site. I think that the results can help in solving the waste problem in the industry.

What is your research process and what kind of technologies are you using?

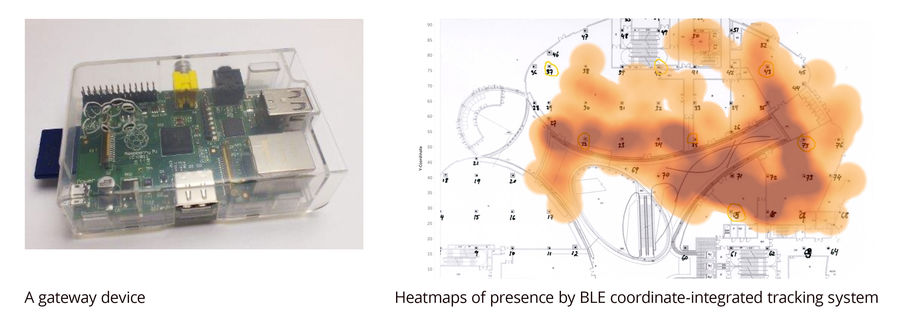

In the first part, I’ve done several case studies in Finland and abroad; including China, the Netherlands, Peru, and Brazil. The second part was to develop a Bluetooth, low energy real time tracking system. This I’ve been doing it together with the School of Electrical Engineering. Furthermore, I’m conducting data mining and analysis and, finally, doing data visualization.

We’ve used Bluetooth beacons like the one I have here. It costs about five dollars and the battery can last one or two months, depending on the transmission power. We attached them to workers. We first asked for their consent and if they were willing to participate. And, of course, we highlighted we wouldn't be collecting any names or identities to protect their privacy.

The beacons were connected to gateways, Rasberry Pi computers, which sent the data to a cloud service.

What kind of insights are you looking to get from the data?

This is kind of a new concept. We want to see the relevance of the presence of the workers on the site to the progress of the task. Our method relies on the beacon to automatically track the start time of a task and the finished time of the task. We have seen that the presence of the worker doing a particular task is not high compared to the total time of the task. This means that there are many interruptions during the whole operation.

We also compared how presence compares with plans. We developed a presence-to-plan ratio to see how much presence is needed to complete the schedule. To go even further, we’ve analyzed the amount of production in relationship to the presence of the workers. This is the only way to understand how much value adding activities they’ve been doing.

Now, I and my supervisor, Professor Olli Seppänen, have finished the data collection phase and are in the middle of writing our third research paper. We have found that, on average, a presence of 34% is needed to complete a scheduled task. In other words, up to 66% of the schedule could be compressed to reach an optimal workflow. That indicates that there’s a huge potential to eliminate construction waste and improve productivity.

Why do you think the worker presence is not optimal today?

Well, one thing I can think of right away is that workers just do not to really follow the schedules. And secondly, of course, there can be a lot of internal task interactions with different dependencies. So, for example, the current tasks couldn't start before the previous one was completed.

What practical and commercial applications could originate from your research?

When we started the project, the initial idea was to shift the conventional management approach to digitalize platforms in construction. Afterwards, we realized that this is actually a good approach for companies to eliminate waste. The Bluetooth technology that we’ve used provides relatively good detection accuracy and a very light, easy, and inexpensive system.

Read more news

Hannu Martola appointed as Chair of the Aalto University Alumni Network Board

The board’s new members are Esa Arola, Eila Lindroos and Terttu Sopanen. Continuing members are Ari Bertula, Laura Nikola and Katja Soini.

VTT, Aalto University and GTK: How to ensure Finland captures the multi‑billion growth potential of mineral economy

Finland is rising to the forefront of the mineral economy through new research initiatives and closer collaboration

Significant donation to boost pavement engineering research and education

Companies and associations in the field have donated €400,000 to the School of Engineering.