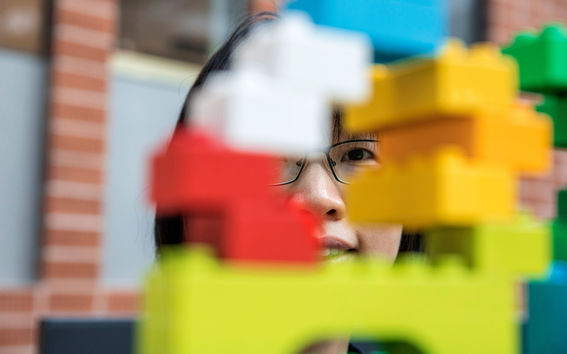

Playing sparked an idea how to transfer tacit knowledge

Professor Yu Xiao and her 2 1/2-year-old daughter sat on the floor and played with Lego. Her little fingers built a variety of structures which would have been difficult for someone else to replicate and make afterwards. Whilst watching her daughter play, Yu Xiao began to wonder if it would be possible to develop a solution that could learn from this kind of activity and automatically transfer the learning to others.

Initially, the idea did not have an application, but after further research, Yu Xiao noticed that industrial companies had a problem to which her idea would fit. These days, instead of mass-produced items only, industrial equipment produce highly personalised products to meet the needs of different customers. The use and maintenance of equipment require expertise, which is often the result of long-term practical work. However, teaching thousands of processes to new employees can be tricky.

As Professor Xiao and her research team started to develop their smart and automatic tacit knowledge education system called ‘cognitive engine’, the Lego bricks transformed in her mind into a variety of industrial equipment and products.

Brain to brain learning

In practice, the system developed by the researchers involves a camera which records how an employee’s hands maintain or assemble a device. From the video the system learns the different work stages, how and in which order the various actions are taken, and the tools and components that are used. When an employee is working on an unfamiliar device, he/she learns through various aids to work like an experienced employee.

The technology monitors the employee’s actions and gives advice when he/she is about to make an error. Time and effort is saved when there is no need for an instructor to be present when teaching new skills. Reliability is also increased when errors cannot be made without the system noticing them. The employee’s stress levels are also reduce as they do not need to worry about making mistakes.

“Practical implementation is still being planned, but we intend to use a number of techniques, such as wearable glasses, smart gloves, and various sensors”, says Yu Xiao.

The purpose is to create a learning experience in which the employee is guided without having to follow written instructions.

“The guidance is invisible, so it does not irritate.”

The project utilises expertise in many different fields, from basic research to artificial intelligence, smart clothing and user experience. The same concept can be utilised in all areas requiring cognitive abilities, even in the teaching of bus drivers or pilots.

Professor Yu Xiao applied for and was granted funding, and now, one year and a half after an idea borne out of playing with Lego, the prototype is in the pipeline. She is confident about the future.

“I believe that in about a year or so we will have a complete prototype and the product can be commercialised.”

- Cognitive Engine for Assembly and Maintenance Automation, also known as the CEAMA project, received €700 000 in Research for Business funding.

Text: Riikka Hopiavaara. Photo: Mikko Raskinen.

This article is published in the Aalto University Magazine issue 23 (issuu.com), October 2018.

Read more news

Stop applying for jobs and build your own startup instead at Ignite

Applications for the Ignite summer accelerator program 2026 are open. Apply by March 8.Soil Laboratory Exhibition – Exploring the Dialogue Between Human and the Earth in Utsjoki

Soil Laboratory explores the relationship between humans and the earth as a living landscape through ceramic practices in Utsjoki.

The Finnish Cultural Foundation awarded grants for science and art

A total of 15 individuals or groups from Aalto University received grants