Complex Systems and Materials (CSM)

Applies statistical physics to a wide variety of cross-disciplinary topics.

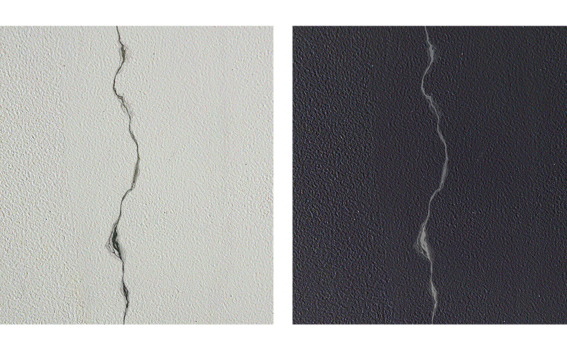

Cracks and faults are everywhere from tiny fractures in aircraft components to stress-induced wear in bridges, pipelines, and medical devices. Predicting when and how faults grow is a key challenge in engineering and materials science. Solving it could help engineers make components, materials and even buildings last longer.

Now, researchers from Aalto University’s Department of Applied Physics have uncovered a new way to describe how structural cracks expand using statistical physics. Their insights help untangle a long-standing paradox in fracture mechanics and could improve the reliability and durability of everything affected by cracks and faults.

The findings were published in Physical Review Letters: https://doi.org/10.1103/PhysRevLett.134.098202.

In practice, materials are subjected to either static or periodic loads. Static loads—for example in stationary infrastructure like buildings—can cause slow creep deformation, and periodic loads—like those in rotating machinery or aircraft structures—lead to fatigue, where cracks advance over many cycles.

‘Fatigue cracks grow faster when stress relaxes between cycles. This has puzzled engineers for years because it would be more intuitive that stress without breaks resulted in faster-growing cracks,’ lead author and Postdoctoral Researcher Tero Mäkinen explains.

Mäkinen and members of the Complex Systems and Materials research group at Aalto showed that cracks don’t grow steadily but advance in intermittent bursts, overcoming microscopic barriers inside the material. This insight, drawn from statistical physics, combined with a new length scale discovered by the team describing the processes happening in the material just before the advancing fault, helps explain the paradox.

‘The work provides a missing link between empirical fatigue models and physics-based fracture theories. We created an experimentally measurable length scale that captures the material’s plasticity history and crack closure effects. This means we can now better predict failure and improve how new materials are designed,’ the group leader Professor Mikko Alava says.

The study provides a new way to describe crack growth in real-world materials, including construction and engineering staples like steel, aluminum and titanium.

‘The results could lead to more accurate lifetime predictions in industries where failure prevention is critical, including aerospace, civil engineering, and medical devices,’ Mäkinen concludes.

The work was carried out using the computational resources from Aalto’s Science-IT project and funded by Research Council of Finland (especially the Fluctuations in Fracture project).

Applies statistical physics to a wide variety of cross-disciplinary topics.

Infrastructure for high-level computational research.