Catalyst could help bleach pulp in seconds

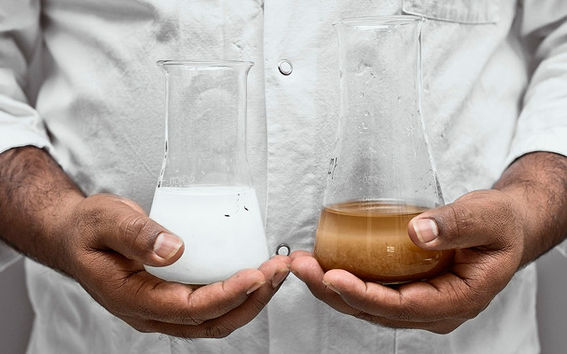

Professor of Forest Products Chemistry Tapani Vuorinen has an idea: he wants to develop the bleaching of pulp mass in a way that enables the end result to be reached in two, or perhaps just one, bleaching stage.

In a way, this involves a return to the past because the bleaching of cotton and linen rags started with a one-stage technique towards the end of the 18th century. Back then, pulp would be manually stirred in a cooking pot while adding chemicals until the mix attained a suitable look – with no-one worrying about precise amounts or environmental impacts.

Over the past two centuries, the quality of pulp has improved, the chemicals have developed and the environmental impacts have reduced in spite of substantial growth in production volumes. But this has also involved the transformation of bleaching into a multi-stage process that consumes time, energy and large investments. Now, Vuorinen and his research group believe they can shorten the duration and increase the effectiveness of the bleaching process by introducing a catalytic bleaching technique developed with the aid of industry companies.

“The catalyst we employ, a tertiary amine called DABCO, reacts with the bleaching agent and boosts its effectiveness considerably. The reaction time of a single stage has, up to now, been close to one hour, but the method we've developed makes it possible, at best, to achieve the same result in less than a second. Traditionally, there have been 4-5 stages, but now, thanks to the catalyst, two stages are enough,” Tapani Vuorinen says to sum up the idea.

Room-sized reactor

For the industry, speeding up the process and reducing the number of stages translates into substantial savings. The building of a modern pulp mill is a sizeable investment, partly because of the demands posed by the bleaching process in particular. The volume of a bleaching reactor may be thousands of cubic metres, and each phase of the process requires its own reactor.

“Building a bleaching unit for a pulp mill with an annual production capacity of one million tonnes can cost upto €200 million because, in addition to the bleaching reactors, it is also necessary to build a chemical plant that manufactures the bleaching chemicals on site,” says PhD candidate Naveen Chenna.

Thanks to the catalyst, less chemicals and only one large reactor are needed, while the other parts of the bleaching process fit into a space the size of an ordinary room. In addition to time, investments and chemicals, catalytic bleaching also conserves energy.

“Reactors can be up to 50 metres high and using steam to heat them to the 80-90 degree temperatures required for existing bleaching methods consumes a huge amount of energy. Catalytic bleaching, on the other hand, can even be performed at room temperature,” Chenna explains.

More selective bleaching

Pulp is most commonly bleached with either chlorine dioxide alone or together with oxygen gas and hydrogen peroxide. It is also possible to perform bleaching entirely without chlorine compounds if ozone and peroxide are employed. Catalytic bleaching utilises hypochlorite, a chemical that has been rejected in the past.

“This is quite a story,” Tapani Vuorinen says. “Hypochlorite, which we use in the catalytic stage, was rejected towards the end of the 20th century because its use creates chloroform. For years, hypochlorite has been an almost taboo subject that the industry has not wanted to talk about; even the coordination group was hesitant about its use. However, our experiments have demonstrated that catalytic bleaching results in lower chloroform emissions than traditional bleaching that utilises chlorine dioxide. In a sense, we've come full circle with this issue, i.e. achieved better environmental results with a once-rejected chemical by doing things in a new way.”

One of the problems with traditional bleaching is the inefficiency of chlorine dioxide. Only part of it is consumed by the desired task, removal of lignin, while the process sees the rest form into chlorate and chlorine, which is bound into the organic compounds of wastewater. In catalytic bleaching, by contrast, the reaction of hypochlorite and DABCO forms a strong electrophile, which reacts selectively with lignin and the other compounds being removed. Traditional chlorine dioxide bleaching also creates a sufficient amount of hypochlorite to realise catalytic bleaching.

Dream within reach

Catalytic bleaching is such a promising invention that all of the companies that got involved three years ago – Stora Enso, UPM, Metsä Fibre, Kemira and Andritz – want to see research continue. It is already known for sure that the catalyst works; the next step is to explore how effectively it can be utilised on an industrial scale.

“We know that DABCO is already used for the industrial manufacture of polymer-based foams, for example. The European Chemicals Agency at present imposes a limit of two kilos per tonne, and we've been using one kilo or less. The markets are, however, international and many countries follow the decisions of the United States Food and Drug Administration, so we'll have to look in to their approval as well,” Chenna explains.

Tapani Vuorinen is optimistic, but emphasises that much yet remains to be researched.

“We are trying to further enhance the efficiency of the process in order to lower catalyst costs. More information about the quality of pulp must also be obtained. The bleaching methods in use at present involve lengthy retention periods and acidic conditions, and this weakens the quality of the pulp. We think that catalytic bleaching can produce pulp of a higher quality.”

The second bleaching stage that follows the catalytic phase must also be made as efficient as possible. PhD candidate Ghazaleh Afsahi has already achieved promising results with ozone. The two-stage combination can yield white pulp in just a few seconds.

“Tapani believes that a reactor may not even be needed in the future, as it might be possible to perform the bleaching in a mixer. We've already gotten quite close to realising his dream of perfecting single-stage bleaching,” Afsahi and Chenna say.

In the picture: Professor Tapani Vuorinen and PhD candidates Ghazaleh Afsahi and Naveen Chenna are developing pulp bleaching with the help of a catalyst and hypochlorite.

Photos: Heidi-Hanna Karhu

The article has been published in the Aalto University Magazine issue 11. Read the magazine.

Read more news

Online Writing retreats for doctoral students in Finnish in spring 2026

Join the monthly communal meetings for research reporting.

Training available in AI, research data management, research ethics + more – register now!

New topics included! Registrations for spring 2026 are open.

New Innovation Postdoc programme launching this spring in Aalto

Innovation Postdoc launching this spring for AI researchers eager to turn cutting-edge research into real-world impact.