Boosting MEP works productivity with design for installation and prefabrication

Tuomas Valkonen is a doctoral researcher at Aalto University, with a career as an energy expert and HVAC designer at Granlund Kuopio. His D.Sc. research was sparked by his interest in industry development and problem-solving. He wants to free designers from rote mechanical work and, at the same time, help installers focus on their core competence.

Although the digitalisation of construction has accelerated, the sector’s productivity and quality development still lag behind other industries. For example, a recent Aalto University study shows that HVAC installers use just slightly over 19% of their work time on actual installation work.

One productivity barrier is the gap between design and installation. To make construction more efficient, on-site work must become more like installation and less like improvisation. This poses new requirements for engineering design, which already struggles with a huge amount of rote work. Valkonen believes that design automation and prefabrication—industrial production of MEP assemblies—would considerably increase MEP engineering and installation productivity.

A more industrialised process with prefabrication

The process and shipbuilding industries use prefabrication abundantly, and the model has been implemented in specific MEP installations. For example, in the Nova hospital project in Jyväskylä, Finland, technical installations for the corridors of patient wards were prefabricated. Factory-made air handling units, substations for district heating, electrical switchboards, and shaft elements for residential buildings are examples where prefabrication is currently used.

There are two types of prefabrication. The first type occurs in a manufacturing environment and resembles a typical industrial process. The second type is pre-assembly, which happens in a dedicated area on the construction site.

Prefabrication speeds up installation, improves worker safety, and makes quality management easier. There are, however, speed bumps in the way of large-scale prefabrication.

Project participants don’t often clearly understand the benefits and beneficiaries of prefabrication. This leads to a low commitment to using a novel method. However, the main obstacle to prefabrication is that it comes in too late during the client’s agenda. Designs are not ready for manufacturing and assembly, which leads to redesign and scheduling changes. In that case, prefabrication wouldn’t add noticeable value.

The necessity of a more detailed production design

Prefabrication increases design engineers’ workload because they must take their designs to a more detailed level to serve installation. Consequently, design for manufacturing and assembly (DFMA) extends beyond current job descriptions. If DFMA is not included in the design commission, someone has to pay for the extra work.

Valkonen wonders whether paying extra would be enough to overcome the challenge of a more detailed design. Engineers might not have enough information about manufacturing requirements. These include the proper installation order, hangers and support structures, and making the right product choices.

Valkonen believes that the answer to installation and prefabrication challenges is automation. Some companies are already developing digital platforms that allow automation of most design routines and data production tasks for manufacturing and assembly.

The problematic practice of installers as designers

Whether assembly is done on the site or in a factory, designs should support it as much as possible. Valkonen studied how the design models and the as-built reality matched in new building and renovation projects. The study revealed that installers make design decisions at the workplace to optimise their work, fill design gaps, or solve conflicts in the drawings.

The exemplary projects confirmed a known issue: many details remained to be solved on the construction site. For example, hangers were missing from the drawings. Installers had added—for practical reasons—cable trays that were not in the drawings. When hangers were not in the drawings, a design engineer could not consider them while placing ducts and pipes or planning the installation order.

Installers may also simplify installations. Sometimes, this is rational, but on some occasions, it leads to collisions when the next-in-line technical system’s space requirements and routes are unknown. A seemingly odd design solution would make sense if the installer studied the coinciding system’s BIM model before starting work. Changes without checking can require, for example, lowering a suspended ceiling, which can lead to unintended consequences.

Design that increases productivity

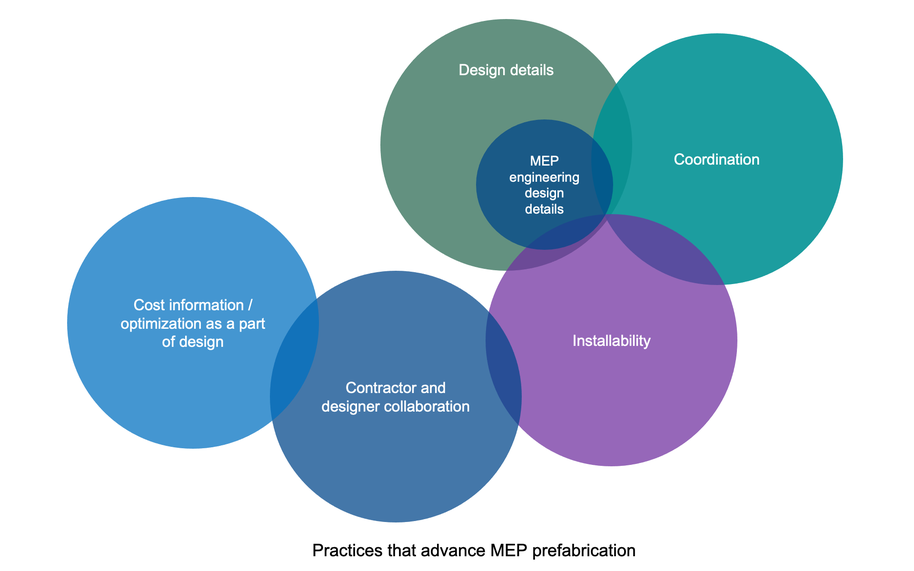

The mere digitalisation of existing processes is not enough to improve construction productivity. Valkonen presents several solutions that together make designs more installation- and prefabrication-ready.

More detailed designs

Increasing the level of detail in design is essential for developing installability and prefabrication. In Britain and the United States, the level of detail in building engineering design is higher than in Finland, so you can use them as a reference. The designers’ workload does not necessarily increase unreasonably either if it is possible to use design automation.

Design with contractors

Those who do installation are the best experts in their work. When contractors participate in design as early as possible, constructability comes to the fore at the right moment. Planning the order of installations and choosing the right components free the contractors from solving problems later on the site.

Increasing repeatability

Combining Takt production with prefabrication can double a construction site's productivity. Takt production best suits projects with repeatable spaces, creating repetition in technical installations. In general, standardisation is essential in manufacturing. For example, Southland Industries in the United States has modularised and industrialized technical engineering to a high degree with standardisation and reproduction.

Matching design models

BIM models of all design disciplines should be collision-free before contractors start to use them. Fixing clashes with design software is considerably cheaper than doing it on the site. Setting aside time for overlapping designs has a high ROI for contractors.

Making design documents illustrative

Until construction robots become mainstream in construction, design models and documents are read and interpreted by humans. At least the largest construction sites utilise BIM models to help plan the installation work. 3D models are superior to 2D drawings because they show all the technical systems together in the same space. In addition, isometric renderings serve prefabrication exceptionally well.

Who benefits?

The previously described changes can significantly increase the industry’s productivity, but individual companies always ask: What’s in it for us? That’s hard to answer without knowledge, so it’s necessary to devise a business case study of the ways of operation.

Sometimes the result of a benefits analysis can be surprising. In particular US design and build projects, contractors have paid substantially for detailed design because its ROI in just one project is higher than that of any traditional investment.

Tuomas Valkonen is continuing his research, hoping that the results inspire discussion and experimentation in a more industrialised way of construction. His suggestion for a quick start is simple: “The best way to move prefabrication forward is to decide to use it.”

Read more news

Apply Now: Unite! Visiting Professorships at TU Graz

TU Graz, Austria, invites experienced postdoctoral researchers to apply for two fully funded visiting professorships. The deadline for expressions of interest is 20 February 2026, and the positions will begin on 1 October 2026.Soil Laboratory Exhibition – Exploring the Dialogue Between Human and the Earth in Utsjoki

Soil Laboratory explores the relationship between humans and the earth as a living landscape through ceramic practices in Utsjoki.

The Finnish Cultural Foundation awarded grants for science and art

A total of 15 individuals or groups from Aalto University received grants