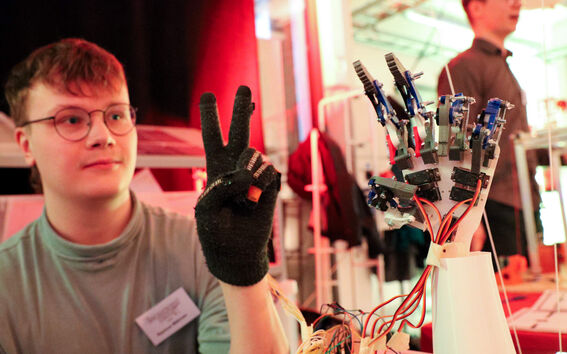

Mechatronic Circus 2025

When

Where

The Circus will take over Otaniemi's Puumiehenkuja block on Thursday, April 3, 2025, when students present the devices they built during the spring mechatronics courses at the Mechatronics Circus event. The event is open to everyone and there is no need to register. Pre-registration for middle and high school groups is closed.

Program from 10:00 to 15:00

Mechanical Engineering Building K3, Puumiehenkuja 5

- 10:00–15:00 Presentation of student projects from mechatronics project courses

- 11:00–14:00 Pea soup and donuts will be available

Student Projects

Bachelor's and master's students' projects are on display in the hall at Puumiehenkuja 5.

Projects from the course MEC-E5002 - Mechatronics Project

Responsible teachers: Petri Kuosmanen ja Panu Kiviluoma

By Muhammad Anis, Lasse Harju, Muhammad Hammad Hussain, Elias Salo

Autonomous navigation of mobile robots relies on various path planning algorithms to determine a collision-free trajectory from a start to a goal position. The effectiveness of these algorithms is influenced by several factors, including computational efficiency, latency, power consumption, and reliability. The selection of an appropriate algorithm is application-dependent, as different scenarios prioritize these factors differently. This paper presents a comparative analysis of three widely used path planning algorithms A* (A-star), Dijkstra’s algorithm, and Rapidly-exploring Random Tree (RRT) in an indoor environment. The performance of these algorithms is evaluated through both simulation and real-world experiments, with key metrics including path length, computational time, and the number of nodes explored. Based on the results, A* provides the optimal balance between path efficiency and computational power. Dijkstra’s algorithm may generate more optimal paths in some cases but at the cost of significantly higher computational time. RRT, while requiring fewer nodes, suffers from suboptimal path quality and higher computational times, making it less suitable for the tested application.

By Veeti Karhu, Leo-Pauli Moisio, André Monteiro Cocco, Jere Paalanen

Overhead cranes are integral to industrial and harbor environments, where they are employed for the elevation and transportation of substantial loads. Safe operation of these cranes is key to preventing workplace accidents and keeping people from getting hurt or worse. Although current safety procedures aim to manage risks, statistics show that accidents persist, indicating a need for improvement. This project proposes a system to prevent the overhead crane hook from getting too close to humans. The system uses a 3D LiDAR attached to the crane trolley to obtain point clouds from the operating area, processing them to detect people in unsafe proximity to the hook. In case of detection too close to the trolley, the crane operator is warned. Therefore, a digital safety zone for the crane is established, improving safety without requiring physical barriers or no-access zones.

By Arttu Heikkinen, Aleksi Heino, Eero Moisio, Hannes Mönkkönen

In this project we go through the process of developing a cost-efficient modular drive by wire kit that allows a car to be controlled with digital signals. The kit is designed to be retrofitted into cars equipped with an automatic transmission. The kit can operate the steering wheel of the car as well as both pedals. Usage of the kit eliminates the need for a human operator to be inside the car, which allows the car to be used in autonomous tasks and hazardous environments. The ability to control the car with digital input allows remote operation or machine vision based control of the vehicle. Remote driving was achieved via a gamepad controller. Machine vision was used to enable human detection, which was used to control the steering.

By Dima al-Nasser, Aadesh Chaudhari, Oliver Häggman, Antti Lindman, Lauri Viljavuori

Ocean energy is an untapped resource that could aid the transition to renewable energy sources. Wave energy converters face challenges such as high-cost, poor efficiency, and harsh environments. This study presented a small-scale wave generation environment to aid rapid and cost-efficient wave energy research. Furthermore, it compared the efficiency of a wing and point absorber converter. Efficiency was compared by measuring the power generated for both converters under similar circumstances. The small-scale wave generator was found successful for generating waves with different amplitudes and frequencies. In addition, the shoreline allowed wave energy converter research in various depths. Tests are currently being conducted for efficiency comparison.

By Leo Kesti, Jaakko Laitinen, Otto Puikkonen, Abdullah Zafar

Aerostatic bearing technology offers a frictionless alternative to conventional elevator guide shoes, reducing noise, vibration, and energy consumption. However, its implementation requires highly precise guide rail surfaces. This study introduces an on-site grinding device designed to achieve the necessary tolerances. The device utilizes an abrasive belt and a spring-loaded contact mechanism to ensure consistent pressure and precise grinding results. A programmable control system enables autonomous movement and precise control of grinding parameters. A prototype was developed and tested, demonstrating the feasibility of the concept with promising results.

By Petteri Haverinen, Arun Jaiswal, Niklas Sterpi, Casper Suominen

This study investigated the optimisation of laser output power in laser-induced breakdown spectroscopy (LIBS) for the purpose of materials and minerals identification in mining applications. A LIBS system was used to determine the minimum laser energy required to produce an emission spectrum from typical materials like rock and mineral samples. As an experimental setup a Galilean telescope arrangement for focusing and a concave mirror for light collection was used. In the beginning, a steel plate target (sample/material under study) was used for spectrometer calibration based on known iron spectral lines. An audio-based focusing method used, and laser energy levels were systematically reduced until the emission spectrum was no longer reliable. Later, many mineral samples, was selected based on their relevance to mining environments, and were tested to determine the lowest viable laser energy for precise identification. Results shared highlights a compact and cost-effective LIBS system for long-range on-site mineral analysis was achievable by identifying the minimum laser energy that still produced reliable spectral data.

By Samuli Ahola, Edward Bagge, Leo Isännäinen, Juhana Kulju, Saad Rana

This concept presents an automated gate between a restricted zone and a cooperation zone in industrial environments for Autonomous Mobile Robots (AMRs). The system employed Radio Frequency Identification (RFID) for authentication purposes and Time of Flight (ToF) sensors for proximity-based safety monitoring. The identification system and the mechanical gate that is opened by a winch rope mechanism are regulated by an Arduino-based controller. Experimentation was done in various conditions, including scenarios with variable AMR behavior such as unscheduled stops or changes in velocity. Results indicated that the gate is able to authenticate authenticated agents while excluding unauthorized agents. This proof of concept’s design offers modularity while being cost effective makes it a potential candidate for various industrial applications. This approach provides a functional method for managing AMR access in controlled settings – surpassing already existing solutions due to its safety and overall design choices.

By Srijit Bashyal, Lucas Foley, Tatu Haakana, Oliver Järnefelt

This study presents a self-positioning crane hook system designed to lift pallets with loads directly from Automated Guided Vehicles (AGVs) or from the floor, without manual intervention. The objective was to enhance the efficiency and safety of pallet lifting operations, addressing the challenges associated with manual handling in industrial environments. The system automatically detected and positioned itself over the pallet, minimizing human involvement and optimizing warehouse logistics. A rigid frame and adaptive mechanical design ensured stable and accurate lifting, while an integrated locking mechanism secured pallets during transportation. During testing, the system successfully aligned and lifted loads of more than 25 kg, with misalignment detection feature preventing unsafe operations. Powered by a rechargeable battery system, the device enabled continuous operation for up to 8 hours, proving its viability for industrial applications. The system’s autonomous pallet handling capabilities mark a significant step toward fully automated warehouse logistics, reducing manual labor while maintaining operational safety and efficiency.

By Onni Leutonen, Aleksi Myllys, Alex Nordensved, Jesper Riihola, Muhammad Zia Ullah

Currently elevators utilize linear sliding bearings for car alignment. The goal of this study was to investigate the usage of porous aerostatic bearings as an alternative to the current solution. Three porous graphite aerostatic bearings were installed in the elevator. The friction force and individual flow rates in operation were measured. Loading the narrow middle bearing causes contact between bearing and the guide rail. Loading of the side bearings on the side of the guide rail had an insignificant effect on the performance. High friction values were possibly caused by geometric error, surface defects and insufficient load carrying capacity of the bearing due to a limited surface area. This study suggests that aerostatic gas bearings are a viable option in elevators, but further research is needed.

Projects from the course KON-C3003 - Mechatronics Exercises

Responsible teacher: Panu Kiviluoma

Course assistants: Jaakko Laitinen and Olli Heino

Petri Tunkkari, Tero Tunkkari

Miska Salonen

Elmo Laine, Petteri Suonpää, Albert Vauhkonen

Lauri Moilanen, Dina Sadojevic Jelacik

Ola Tirkkonen

Johan Kärki

Niklas Kujala, Arttu Rintala

Joonas Dahlqvist, Daniel Hillberg, Lukas Parviainen

Daniel Söderlund

Pekka Porkka

Anniina Haka, Jere Markkinen, Aksel Ilveskero

Elis Talonpoika, Casimir von Knorring

Eelis Lumpo, Peppi Tarkka

Kevin Mäenpää, Oscar Olander, Otto Sundell, Eddie Sundström, Martin Wärnå

Lauri Ahola

Jaakko Aalto, Mikhail Romanov

Hugo Tamm

Ilkka Etula

Lauri Bystroff, Aleksi Seppänen

Research projects

ARotor lab

ARotor laboratory is a full scale rotor laboratory with facilities to manufacture and investigate rotors of up to 25,000 kg.

By Mikael Miettinen, Valtteri Vainio, Onni Leutonen, Petteri Haverinen, Luke Harding

Airbearings are gas lubricated bearings, which enable high-speed precision motion with low friction. Airbearings have interesting new appications in production machinery, where increasing demands on quality and energy consumption make traditional solutions infeasible.

By Aku Karhinen, Osma Ovaskainen, Topias Turunen

The device is a scale model of a ship’s powertrain. Monitoring the condition of ships is challenging due to changing conditions and operating environments. The device has been used to create condition monitoring datasets for training intelligent condition monitoring methods, and it can be utilized as a test environment for research.

By Kalle Kinnunen, Veeti Karhu, Henry Kristianto

Electrical runout is a measurement error in eddy current sensors caused by the material of the measured target. Electrical runout can cause significant measurement errors to micrometer-scale displacement measurement. The research investigates the root causes and mitigation of electrical runout.

By Sampo Haikonen, Seth Altobelli, Huy Nguyen, Leo-Pauli Moisio

The quality of paper can be analyzed by measuring paper samples in the laboratory or on the paper machine during production. In our laboratory, we use a paper analyzer that allows us to measure the thickness of paper from samples that are kilometers long. Thanks to the measuring device, we obtain data for analysis that allows us to assess the performance of the paper machine. Therefore, paper quality reveals important information about the machine's operation, such as the condition of the rolls, vibration, or adjustment issues.

By Urho Hakonen, Sampo Laine, Eetu Nieminen, Oliver Häggman, Sampo Haikonen

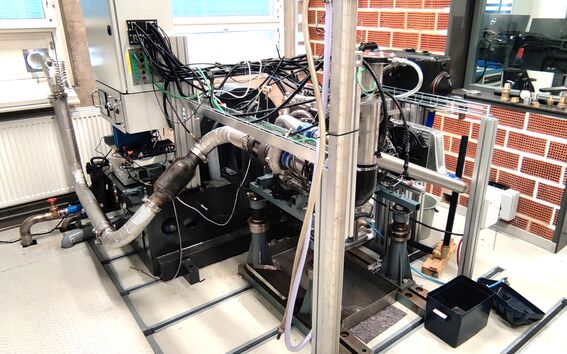

Small-scale maritime thruster testbench can be used to emulate the operating conditions of a full-scale thruster. Torsional vibration analysis is an important part of maritime powertrain design procedures. The small-scale thruster testbench is used in developing torsional vibration analysis and simulation methods.

Omar Morad, Thomas White

The two test devices have been built to help study the frictional, wear, and thermal behaviors of marine thruster lip seals. Due to their relatively large size (designed to run on shafts 300 mm), these seals are seldom studied in the literature. The test devices offer a robust means to investigate the behavior of marine thruster lip seals, particularly their difficult to estimate thermal behavior.

Autonomy & Mobility Lab

Autonomy & Mobility laboratory is at the forefront of automated driving technologies, with a focus on the challenging winter conditions.

By Hari Prasanth S.M.

A method to improve the accuracy of lidar-based localization for indoor mobile robots by estimating the covariance of scan-matching through planar features extraction. In real-world conditions, lidar scan-matching might not be accurate and leads to localization failure. This research aims to address this.

By Pejman Habibiroudkenar

The primary objective is to develop a robust approach for generating point clouds by integrating data from LiDAR, IMU, and wheel odometry. Currently, robots at CERN are controlled via teleoperations, which not only is time-consuming but also less efficient than it could be. By creating an accurate map of the environment, fully autonomous missions can be enabled.

By Kaarlo Mäkelä

Controlling electric motors according to a hybrid truck simulation and measuring their energy consumption. Getting accurate results on energy consumption before vehicle testing makes the vehicle's design process faster, cheaper and less risky.

By Eelis Peltola

Estimating depth from a single camera to generate pseudo-lidar data for autonomous driving. Lidar data is often sparse, and methods trained for one lidar sensor might not work well with others. This work aims to help lidar-based methods generalize better, and allows datasets and methods for cameras to translate to lidar.

By Aleksi Pippuri

A method for high-level data fusion of vehicle location data gathered by a connected vehicle and static sensors. Multi-source collaborative perception enables enhanced situational awareness for traffic control systems and connected vehicles, which in-turn can reduce accidents and increase traffic flows.

By Eerik Alamikkotervo

Method that can automatically label the road in challenging winter conditions just based on the driving history. Increased robustness achieved by fusing lidar and camera. The work is important for enabling automated driving in winter conditions.

By Nilusha Jayawickrama

Vision-based method to improve the capability of exclusively obtaining instances of moving vehicles within a specific proximity around an ego-vehicle, by integrating flow vector analysis with tracking within a 2D feature space. Detecting moving vehicles is an important functionality for autonomous driving mainly as it reduces false alarms, and enhances road safety by making way for more proactive control strategies. The work therefore aims to contribute towards better prediction explicitly of moving vehicles, effectively preventing collisions and unnecessary abrupt maneuvers.

DigiTwin lab

DigiTwin lab researches digital transformation of industry, focusing especially on the Industrial Internet of Things, Information Integration, and Metaverse technologies.

By Sucharitha Kandawalage

Part of TwinFlow project examining material flow in intralogistics. Simulation of MQTT communication between information systems in a factory. The solutions relies on ontologies to ensure interoperability between systems.

Improving situational awareness enables holistic approach for optimizing production. In addition, exchanging information between systems enables traceability of the products.

By Riku Ala-Laurinaho, Albert Dömötör, Haitham Al-Shami

Part of Co-Des project that examines automating ship powertrain design. The interface allows defining system structure for system analysis. It fetches the components from Digital Twin Web, reducing the amount of manual work.

The interface facilitates the design of ship powertrains by providing a visual user interface for defining systems. The interface reduces the manual work of searching for component information.

Fluid Power Laboratory

Laboratory's research focuses on improving energy efficiency and efficiency of design of mechatronic systems with high power requirements, such as non-road mobile machines (NRMMs).

By Profs. Jari Vepsäläinen, Mika Järvinen, Dr. Jyrki Kajaste, Dr. Ali Mohammadi Sefidan, MSc Anna-Kaisa Korhonen, MSc Sanyog Lamsal, MSc Ganesh Neupane, BSc Kivi Knuuti, BSc Heikki Lagus

There is an abundance of low temperature (under 100 °C) waste heat in industrial processes left unutilized. In this project, an actuator is developed that converts low temperature waste heat in process industry into work using thermal swing adsorption. Different designs are explored and compared to maximize power and the speed of the actuator. Utilizing the unused waste heat has a potential to significantly impact to the energy use of the industry sector.

By Prof. Jari Vepsäläinen, Dr. Olof Calonius, MSc Juho Lehto, MSc Topias Tyni, MSc Fletcher Porter, MSc Jaakim Lastunen

The aim of this project is to focus on improving the energy efficiency of mobile machines and make the design of such machine more efficient. New system architectures are studied with simulations and experiments. The design process is made more efficient by developing AI-assisted system design tools. We are developing novel, innovative and sustainable machines and AI assisted engineering tools.

Energy and Conversation Systems

The ECS laboratories focus on researching and studying carbon-neutral energy systems. ReLab is an experiential learning space for energy technology phenomena, and the Internal Combustion Engine Laboratory conducts research on future fuel solutions.

By Prof. Ossi Kaario, Olli Ranta, Otto Blomstedt

A single-cylinder test engine used to study new carbon-neutral fuels and their combustion processes. Research on the combustion of new fuels is at an early stage and many options are still being mapped out.

Prof. Mika Järvinen, Dr. Muddasser Inayat

Bubbling fluidized bed gasifier is used to carry out the thermal conversion of plastics and biomass through steam gasification or pyrolysis. It can also be used to capture CO2through catalytic absorption. It is used to convert solid waste materials to valuable biofuels and chemicals.

Prof. Ossi Kaario, Dr. Qiang Cheng, MSc Otto Blomstedt, MSc Olli Ranta

The Engine Lab at Aalto University is dedicated to experimental research on internal combustion engines, with a strong focus on alternative fuels, emissions reduction, and advanced combustion strategies with single cylinder research engine APEX and optical LEO2. It supports both fundamental studies and industry-driven projects to develop cleaner and more efficient propulsion systems.

Prof. Ossi Kaario, Otto Blomstedt

Engine technology teaching laboratory where you can learn the basics of combustion engine technology. The turbocharged petrol engine is instrumented and used in various laboratory exercises. You can also build an engine as a project in the space.

Prof. Mika Järvinen

RELab is THE PLACE where students and staff can test their own projects and prototypes for energy applications, both research and teaching of solar PV panels, wind turbines, small steam power plant with emission measurements, energy storage systems and general measurements in energy.

This year RELab hosts the wind energy converter project, come to see our aquarium and waves!