Trace metal analysis (2023-2024)

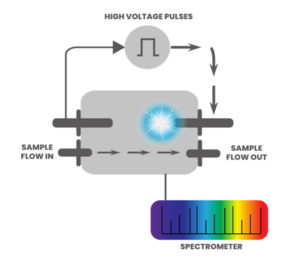

Trace metal analysis is crucial for identifying and quantifying metals in samples. While these metals are essential for well-being, excessive levels can have a detrimental impact on the environment. The rapid advancement of technology has posed challenges to current waste management systems. Numerous studies (Li et al. 2019; Boyden et al. 2016; Mrozik et al. 2021) have demonstrated how electronic waste contaminates groundwater, surface water, and soil through leaching. To uphold environmental health, continuous monitoring of trace metals is imperative. State-of-the-art methods such as atomic absorption spectroscopy (AAS), inductively coupled plasma optical emission spectrometry (ICP-OES), and inductively coupled plasma-mass spectrometry (ICP-MS) are commonly used but lack the capability for fast, real-time, on-site measurements. Sensmet's microplasma-based analyzer has shown promise for providing on-site real-time measurements. This innovative technology creates an electric spark directly within the aqueous sample, heating a microscopic volume of the surrounding water to approximately 10,000 K. Molecular species in the micro-discharge are dissociated into atoms, excited to higher electronic states, and emit light at characteristic wavelengths upon returning to their ground state. The analyzer's sensitivity ranges from µg/L to sub µg/L and can simultaneously identify more than thirty metals in samples. Its compact and robust design makes it suitable for both laboratory and on-site measurements. Aalto's primary objective is to characterize the instrument and evaluate its performance in environmental sample analysis. The joint project has already shown promising results, with the ability to detect trace metals at very low concentrations in aqueous samples (Das et al. 2023). This has significant implications for various industries, such as metal production and recycling, environmental monitoring, and semiconductor industry.

References:

- Li, H., J. Dai, A. Wang, S. Zhao, H. Ye, and J. Zhang. 2019. Recycling and treatment of waste batteries. IOP Conference Series: Materials Science and Engineering 612:052020.

- Boyden, A., V.K. Soo, and M. Doolan. 2016. The environmental impacts of recycling portable lithium-ion batteries. Procedia Cirp 48:188-193

- Mrozik, W., M.A. Rajaeifar, O. Heidrich, and P. Christensen. 2021. Environmental impacts, pollution sources and pathways of spent lithium-ion batteries. Energy & Environmental Science 14:6099-121.

- Das, S., K. Blomberg von der Geest, A. Mäkinen, A. Roos, E. Ikonen, and T. Laurila. 2023. Sensitive Detection of Metal Concentrations in Aqueous Solution Using Real-Time Micro-Plasma Emission Spectroscopy, Analytical Letters, published online https://doi.org/10.1080/00032719.2023.2294358.