Capillary manipulation & microassembly

main / research / capillary manipulation and hybrid microassembly

Fine motion planning and control are key tasks in robotic manipulation, typically involving advanced algorithms. Achieving high-precision fine motion is challenging at high speeds due to the increased difficulty in accurately predicting and controlling the robot's trajectory. Moreover, disturbances such as mechanical vibrations, sensor noise, and environmental forces further complicate achieving precision, especially when manipulating micro-objects.

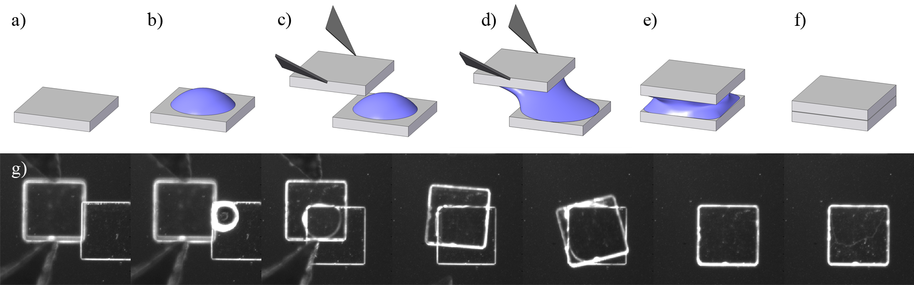

In this line of research, we address the dual challenges of high-speed fine motion planning and high-precision fine motion control using a physical process known as capillary self-alignment. The principle behind this method is that the robot can bring an object close to its target site quickly but with limited precision. At the target location, a droplet of liquid is introduced, creating surface tension forces that pull the object into precise alignment with the target. This approach leverages the inherent properties of fluids to achieve a level of precision that can be difficult to achieve using normal robotic control.

We have conducted extensive research on capillary manipulation and surface-tension-assisted hybrid microassembly, including the first extensive study of how self-alignment and robotic pick-and-place can work together, how different process parameters, including surface wetting properties, topographical features, fabrication precision, and material softness, affect the surface-tension driven (or capillary) self-alignment. We have also carefully studied how the initial position bias of the microcomponent affects the self-alignment and microassembly results.

The work has also been applied to the integration of semiconductor chips, laser diodes, and 3D integration of microchips, including integration into an industrial pilot study in the EU FP7 project FAB2ASM where Prof. Zhou was the coordinator.

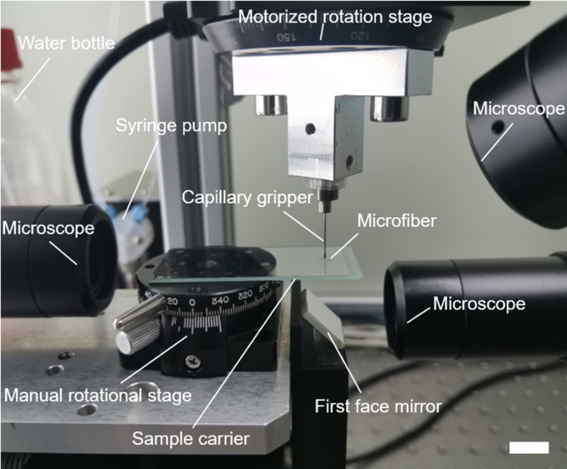

We have also developed different capillary manipulation techniques, e.g., capillary manipulation methods for pick-and-place of microchips, soft ribbons, and microfibers, as well as self-alignment capillary grippers for microchips and microfibers.

Selected publications:

- Sariola, V., Jääskeläinen, M., and Zhou, Q., “Hybrid microassembly combining robotics and water droplet self-alignment”, IEEE Transaction on Robotics, Vol. 26, Issue 6, pp. 965 - 97, 2010.

- Song, L., Chang, B., Feng, Y., Jin, J. and Zhou, Q., 2023., "Self-Alignment Capillary Gripper for Microfiber Manipulation", IEEE/ASME Transactions on Mechatronics, Vol. 28, Issue, pp. 1957 - 1965, 2023.

- Chang, B., Liu, H., Ras, R. H. A. and Zhou, Q., Capillary Transport of Miniature Soft Ribbons, Micromachines, vol. 10, no. 10, p. 684, Oct. 2019.

- Mastrangeli, M., Zhou, Q., Sariola, V., Lambert, P., “Surface tension-driven self-alignment”, Soft Matter, 13 (2), 304-327, 2017.

- Chang, B., Zhou, Q., Wu, Z., Liu, Z., Ras, R. and Hjort, K., Capillary Self-Alignment of Microchips on Soft Substrates, Micromachines, vol. 7, no. 3, p. 41, Mar. 2016.

- Chang, B., Shah, A., Zhou, Q., Robin, R., Hjort, K., “Self-transport and self-alignment of microchips using microscopic rain,” Scientific Reports, 5, 14966, 2015.

- Routa, I., Chang, B., Shah, A., Zhou, Q., “Surface Tension Driven Self-alignment of Microchips on Low-precision Receptors”, IEEE Journal of Microelectromechanical Systems, vol. 23 (4), pp. 819-828, 2014.

- Shah, A., Chang, B., Suihkonen S., Zhou, Q. and Lipsanen, H., “Surface-tension Driven Self-alignment of Microchips on Black Silicon Based Hybrid Template in Ambient Air”, IEEE Journal of Microelectromechanical Systems, Vol. 22 (3), 739 – 746, 2013.

- Chang, B., Shah, A., Routa, I., Lipsanen, H., and Zhou, Q., "Surface-tension driven self-assembly of microchips on hydrophobic receptor sites with water using forced wetting," Applied Physics Letters, Vol. 101, no. 11, 114105 (5 pp), 2012.

- Chang, B., Sariola, V., Aura, S., Ras, R.H.A., Klonner, M., Lipsanen, H., and Zhou, Q., “Capillary-driven self-assembly of microchips on oleophilic/oleophobic patterned surface using adhesive droplet in ambient air”, Applied Physics Letters, vol. 99, 034104, 2011.