Printing Technology

Our research areas:

-

Functional printing

-

Fluid-pore interactions

-

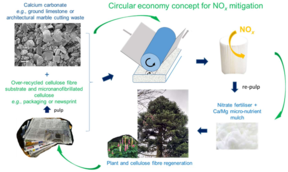

Sustainable materials in circular economy

Our activities include:

- Interaction of fluids with surfaces;

- Development and study of functional printed devices, such as microfluidic analysis platforms;

- Functional coatings including their use based on sustainable and biomaterials for environmental and circular economy applications.

Research Strategy:

The research group is active in developing highly porous functional coatings to meet growing technology challenges in which liquid-surface interactions drive analytical tools, diagnostics, pharmaceutical analysis and security features. Designing the rheological and particle interaction properties of complex suspensions provides the backdrop to the research strategy, additionally providing the opportunity for a multidisciplinary role within the department’s Bioproducts and biosystems research activities.

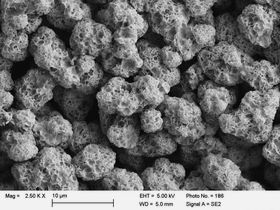

1. Highly Porous Custom Coatings:

We develop highly porous coatings utilising a functionalised calcium carbonate pigment (FCC). The coatings can be customised by using pigments with different specific surface areas and particle sizes, together with charge modifiers and binders, such as microfibrillated cellulose (MFC). Our research topics include studying the wicking speed of liquids in contact with porous coating media, and the use of custom surface treatments to generate a platform for chromatographic separation to provide material separation and reactive microfluidic analytical devices.

Functionalised pigment coatings:

The FCC pigment has a bimodal pore size distribution, which enables fast absorption by high capillarity in intra-particle pores and high permeability through inter-particle voids.

New applications:

New applications for functionalised calcium carbonate (FCC) based coatings include microfluidic devices such as paper-based reaction assays and enzymatic assays as well as medical diagnosis, environmental monitoring and laboratory research tools.

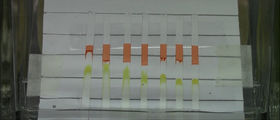

Wicking speed and chromatographic separation of components:

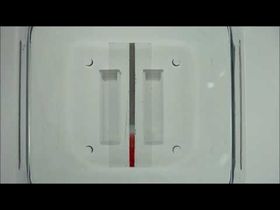

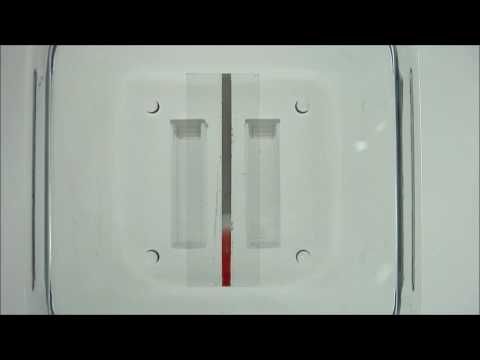

We have developed methods to test the wicking speed and chromatographic properties of the coated samples. For example, this video shows the separation of water and the anionic amaranth colorant on slightly cationic FCC coating in a horizontal test set-up (12x speed).

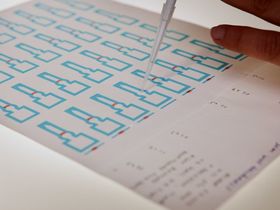

2. Functional Inkjet Printing:

We investigate inkjet printing as a method to functionalise porous materials to produce analytical platforms. Custom inks are being developed to modify localised pore surface chemistries to control flow of aqueous liquids (by selective hydrophobisation) or concentrate/separate ionic molecules (by surface charge modification). As part of the research, methodologies to evaluate the ink/substrate interaction and effect of functionalisation are also being developed.

Fabrication of hydrophobic patterns:

Test patterns are fabricated by printing hydrophobic inks on porous substrates with a DMP-2831 inkjet printer.

Inkjet printed reaction arrays:

The hydrophobising agent amount needed to form a waterproof barrier depends on the properties of the coatings. The effectivity of the barrier can be controlled by varying the hydrophobising agent, drop spacing and number of ink layers.

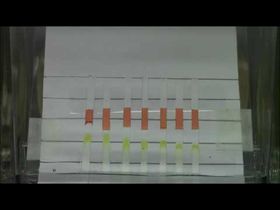

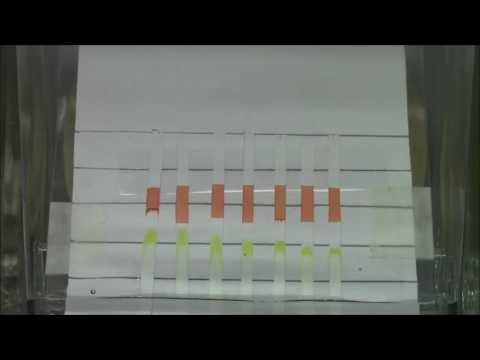

Changing the charge of the coating by inkjet printing

Inkjet printing can be used to effect the desired transfer and separation of compounds in the coatings by changing the charge of the coating regionally. For example, this video shows the concentration of anionic tartrazine colourant (yellow) from wicking aqueous solution on printed cationic polyelectrolyte regions.

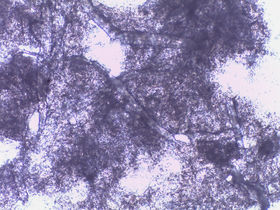

3. Rheologically induced material interactions:

The ability to induce designed inter-species adsorption of particulate material within a gel suspension using controlled rheological conditions is a breakthrough technology centred on the emerging application of micro and nanocellulose in nanofunctional devices and processes. The adsorption of nanoparticles onto nanofibrils of cellulose whilst maintaining a gel-like condition is a discovery of particular significance in a wide range of applications, both in medical and analytical research, and in industry. One such potential application is the analysis of nanoparticles in suspension using gellant microfluidic devices, including a potential solution to the challenge of dewatering nanomaterials.

Collaborations with other universities and companies:

Our network of joint projects include:

| Finland: | Europe: | Other countries: |

|---|---|---|

Research-related videos:

Patrick Gane, Head of the research group"We specialise in front line activities in functional applications to aid sustainability and circular economy"

Research group members:

Related content:

TAPPI awards Professor emeritus Patrick Gane “Outstanding Educator”

TAPPI awards Professor emeritus Patrick Gane “Outstanding Educator”

Professor Patrick Gane receives the prestigious Georg-Jayme Medal

Professor Gane was awarded for his achievements in paper printing and novel pulp applications.

Awards and honours for professors of the School of Chemical Engineering

Prof. Orlando Rojas, Prof. Patrick Gane and Prof. Eero Kontturi of the Department of Bioproducts and Biosystems, have been acknowledged for their significant work.