Plant design

Our research areas:

- Techno-economic assessments of plant scale processes

- Process and plant design for bio-based, sustainable products

Research:

The research in Plant Design focuses on process feasibility study, synthesis, design, operation, integration, simulation and optimization, as well as inherent safety, occupational health, pollution prevention and industrial risk. The key theme is the development of systematic methodologies to identify optimum, sustainable and creative strategies that lead to process intensification, yield improvement, debottlenecking, costing, safety, pollution prevention and energy conservation. Fundamental chemical engineering principles are coupled with systems engineering approaches to develop methods and computer-aided tools that are applicable in all areas of chemical process industry.

Current research projects:

1. Modeling and scale-up of centrifugal filtration:

The project is planned to aid the industry, especially pharmaceuticals field, to make better investments and have better abilities to represent their scenarios computationally without the need to experiment in large scale production.

2. CEforestry:

The objective of CEforestry is to develop new and innovative practices, including circular economy concepts, in forestry. Main goal is to utilize forestry side streams (bark, needles, cones etc.) in Baltic Sea Region.

3. BIO4P - Bioproducts From Nature

Our focus is on developing sustainable processes to produce various extractives, such as essential oils and waxes, from the novel bio-based raw materials. Additionally, the project will assess the feasibility of these processes on an industrial scale and develop business models to exploit their commercial potential.

4. Modelling of solids in porous separation processes:

This research aims to develop models close to industrial scale to replace costly experiments and scale-up studies.

Read more

5. Multipurpose fungal Biorefinery (MultiFUN) project:

This research aims to produce mushroom mycelia as a protein alternative using a two-stage fermentation process through white biotechnology. The primary goal is to design an industrial process and assess its technical, economic, and sustainability feasibility.

- Green solvents

- System intelligence and human factor for ‘super safety’ in manufacturing industry

- COLIAD -Production process of colloidal lignin particles

- Abatement and analysis of greenhouse gas emissions

- Waste to–W2

- Hydrodeoxidation of fatty acid esters for biofuels

- Partial wet oxidation of biomass

- Design and evaluation of biorefinery concepts

- Solid recovered fuel (SRF)

- Digitalization of chemical reactors –KAAPO

- LignoSphere -spherical lignin particle as a platform material for sustainable adhesives and beyond

- iCom-sustainable fibers with ionic liquid

- NovelBaltic

- SO4 Control

Education:

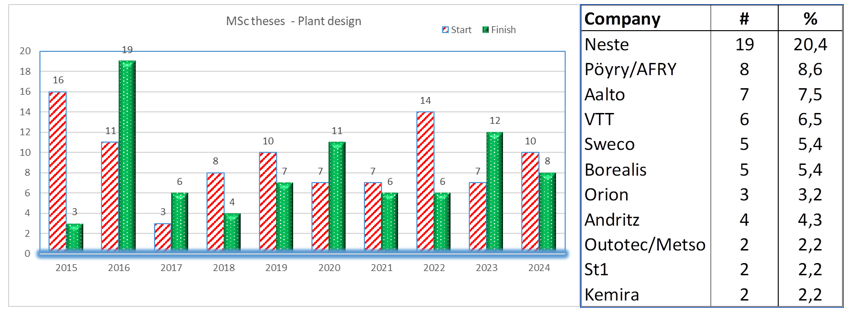

The education in Plant Design is directed at process design and development methods in B.Sc, M.Sc and Ph.D levels. This includes preliminary process design, process synthesis, cost engineering, process simulation and environmental and safety aspects of design. This knowledge can be used for the development of new processes, engineering of new plants and improvement of existing ones in the chemical, petrochemical, biofuel, pulp and paper, minerals, food and biotech and pharmaceutical industries. The teaching is based on problem-based learning, in which process design and development problems are solved using modern design tools such as simulation programs and other design methods. The teaching also includes advanced practical design projects performed as group work and guided by industrial engineers from appropriate companies.

Design Project in Chemical Engineering:

Students participate in their Master's studies in a practical design project, which is based on group work and problem based learning with innovations.

Chemical engineering design project brings mutual benefit to companies and students

The Design project in chemical engineering lets groups of students draft a preliminary implementation plan on topics offered by companies collaborating in the course.

Plant design research combines fundamental chemical engineering principles with systems engineering approaches to develop methods and computer-aided tools that are applicable in all areas of chemical process industry. Therefore, the students graduated have a solid basis for various positions in industry and academy.

Research group members:

Related news:

Chemistry and business students developed plant-based products with Valio

A team of two Master’s students collaborated with Valio in a 6-month Aalto Thesis project.

IonCell-F won the price in pitching

IonCell-F has won seed fund award at Innovation Day pitching organized by Climate-KIC Nordic.