The cost of ‘fast fashion’ – Up to 92 million tonnes of waste and 79 trillion litres of water consumed per year to make garments

Fundamental changes to the fashion business model, including an urgent transition away from ‘fast fashion’, are needed to improve the long-term sustainability of the fashion supply chain, argue Kirsi Niinimäki and colleagues in their article published in Nature Reviews Earth & Environment, a new online journal launched in 2020 within the prestigious Nature family of scientific journals.

The fashion industry is the second largest industrial polluter after aviation, and accounts for up to 10% of global pollution. However, the industry continues to grow, despite rising awareness of the environmental impacts, in part owing to the rise of fast fashion, which relies on cheap manufacturing, frequent consumption, and short-lived garment use.

The authors identify the environmental impacts of the fashion supply chain, from production to consumption, focusing on water use, chemical pollution, CO2 emissions and textile waste. For example, the industry produces over 92 million tonnes of waste and consumes 79 trillion litres of water per year, with developing countries often bearing the burden for developed countries. These impacts highlight the need for substantial changes in the industry, including deceleration of manufacturing and introduction of sustainable practices throughout the supply chain, the authors say.

“Slow fashion is the future”, Niinimäki and co-authors conclude, but “we need a new system-wide understanding of how to transition towards this model, requiring creativity and collaboration between designers and manufacturers, various stakeholders, and end consumers.”

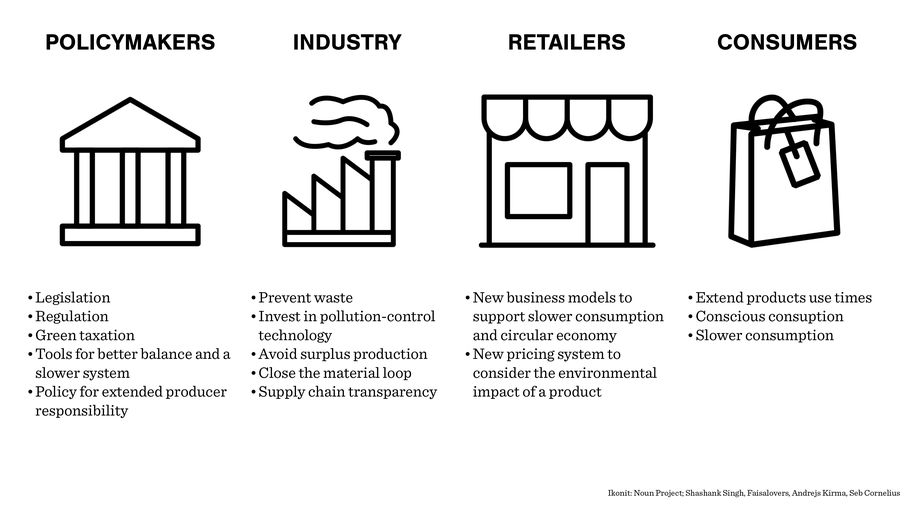

A joined-up approach is required with the textile industry investing in cleaner technologies, the fashion industry developing new sustainable business models, and policy-makers modifying legislation. Consumers also have a crucial role and must change their consumption habits and be ready to pay higher prices that account for the environmental impact of fashion.

Article:

Niinimäki, K. Peters, G., Dahlbo, H., Perry, P., Rissanen, T. and Gwilt, A. (2020) The environmental price of fast fashion. Nature Reviews; Earth and Environment

Nature Reviews Earth & Environment

For more information:

Kirsi Niinimäki, [email protected]

- Published:

- Updated:

Read more news

Maintenance break in ACRIS on 30th of September, 2024

Maintenance break in ACRIS on September from 10:00 to 16:00.

Aalto students' public art projects featured at award-winning ANTI-Festival

Last week in Kuopio, a fascinating collection of public art projects was presented by students from Aalto University's Department of Art and Media.

The butterly effect – bending and turning artificial muscles with light

In the future, the innovation could be used in for example the development of smart textiles, soft robotics and medicine.