Natural luxury – 3D-printed wooden crystals make fashion shine

Biomaterials and 3D-printing conjure a sparkle out of wood without harming people or the environment

Text: Minna Hölttä

Photos: Mikko Raskinen

Videos: Anna Berg

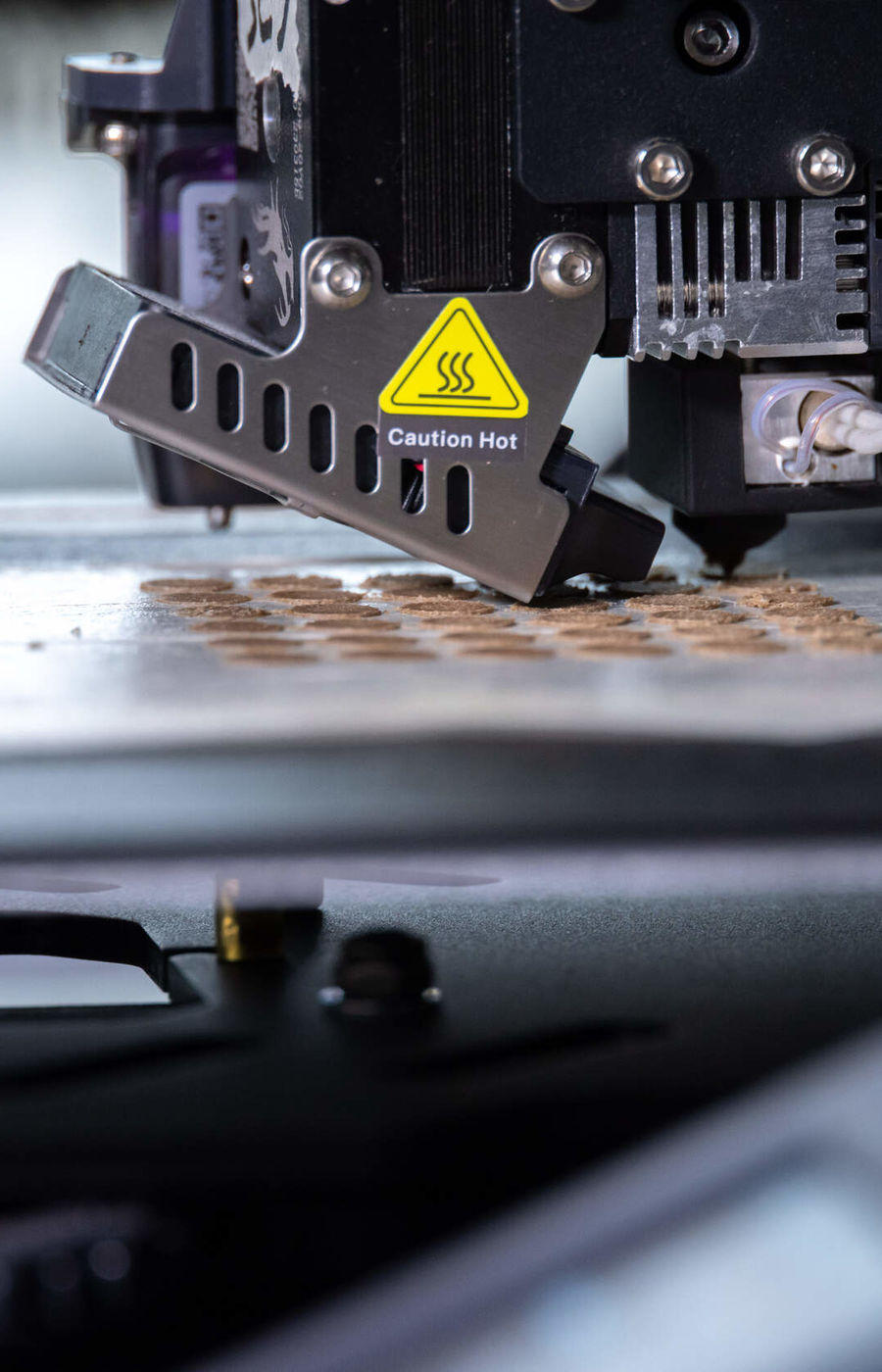

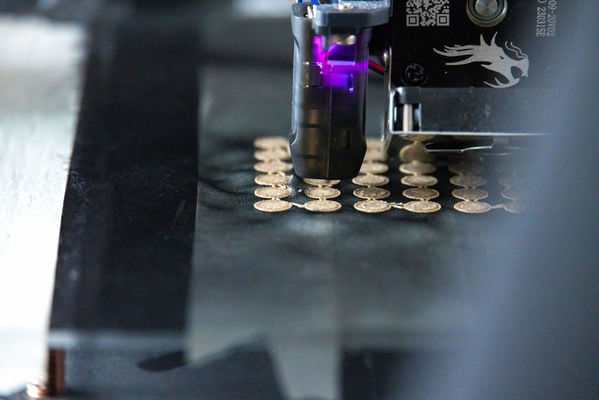

In the corner of a small Finnish workshop, a 3D printer is depositing wooden crystals onto black silk organza. These crystals are a gift to a fashion industry struggling with sustainability in a world where humans love things that sparkle.

Developed by three students at Aalto University, Noora Yau, Anna Semi and Konrad Klockars, the wooden crystals shimmer and shine in different colours, offering an alternative to the plastics and other synthetics used to make clothing glitter. Plastics in clothing eventually break down into microplastics in our environment, and the damage these cause has led the European Union to set a target of reducing microplastics by 30% by 2030.

A beetle’s beauty

Design student Noora Yau and materials scientist Konrad Klockars have been developing Shimmering Wood for years. It’s a wood-based dye that’s based on structural colour, which means the colour is created by nanostructures instead of by pigments.

The nanostructure of Shimmering Wood reflects just one wavelength of light and lets the rest pass through. The reflected wavelength goes back in a specific direction, just like in a mirror, which is why the structural colour is so bright and intense. The colour also varies from direction to direction, because the viewing angle determines which wavelength is reflected to the viewer’s eye.

The bright colours of beetles, peacocks and butterflies are examples of structural colour in nature. Humans have known how to make structural colours for more than half a century, but they’re usually made from plastics and metals containing lead or other toxic substances.

But Shimmering Wood is made from nanocellulose, which is just a part of wood that’s been processed. It’s non-toxic, biodegradable and renewable, and it’s already used in medical applications and composites.

Anna Semi, then a fashion student, worked with Yau and Klockars to create a dress decorated with patterns cut from wood and treated with Shimmering Wood. The dress had admirers but also attracted some criticism.

‘We were told we were just making unnecessary decoration,’ says Semi, who now teaches fashion at Aalto. ‘For this new project, we decided to make that criticism our thing and really embellish.’

Taking the collection to the world

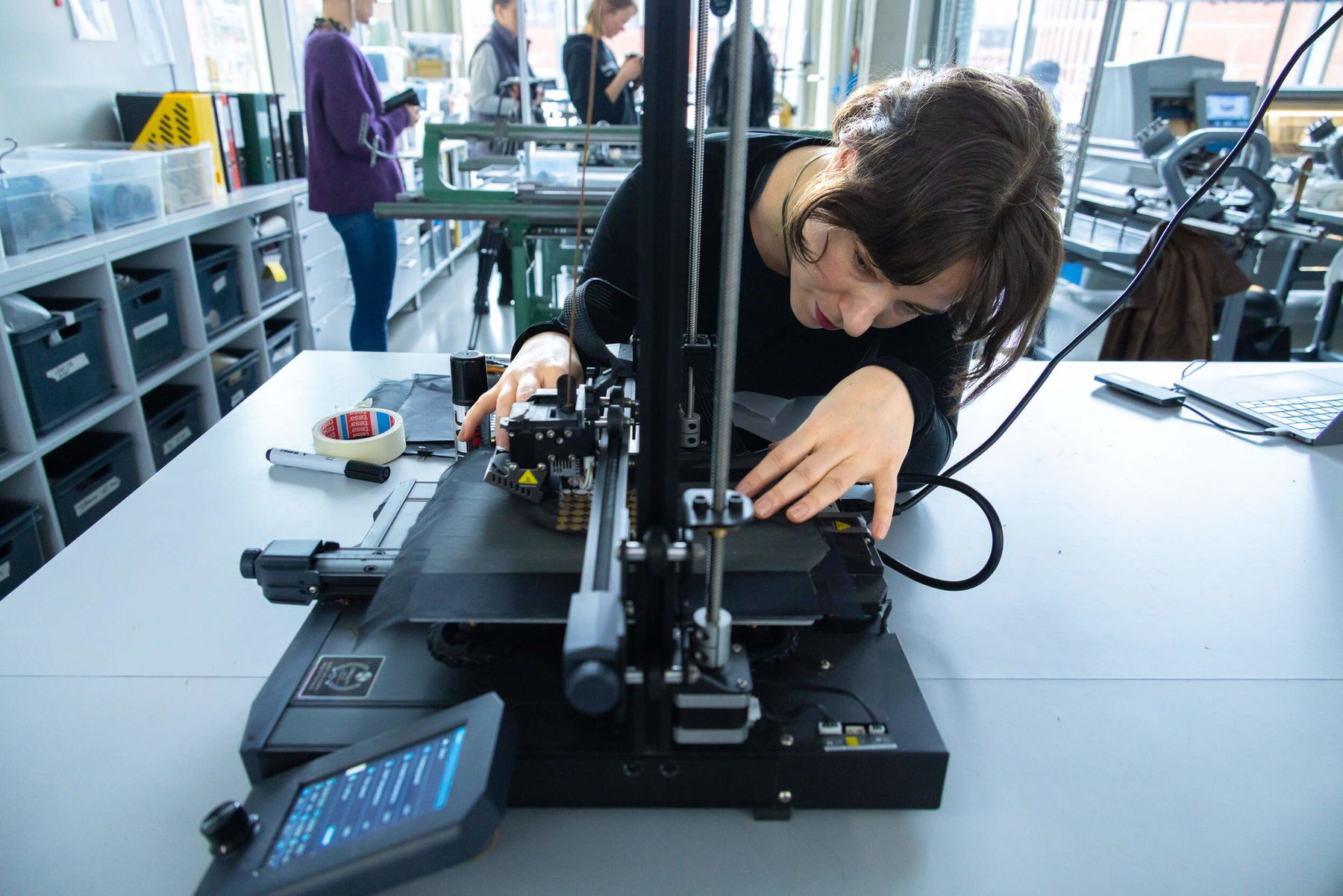

Last year, the trio received funding for experimental work from Aalto’s Department of Design. The aim of the project is to find new ways of using Shimmering Wood in clothing.

‘Using nanocellulose in soft materials is quite challenging. We came up with an idea: what if we thought of the material as Swarovski-like crystals that go directly on top of the soft material,’ says Yau.

Yau, Semi and Klockars decided to 3D print the wood crystals because that would make it easier to scale up the process for commercial production later. The filament used by the printer is a mixture of wood flour and bioplastic that resembles very fine sawdust. The team decided to use silk organza as the fabric so that all the materials would be biodegradable and natural.

Once the wooden crystals are printed onto the fabric, they’re complemented with the nanocellulose colour coating. The crystals are 8 mm in diameter and are round, explains Yau. ‘We did a lot of experiments, and the shape and size were chosen to get the most intensity out of the colour.’

Working with a new, innovative material also requires a lot from a fashion designer, says Semi. ‘I can come up with any design, but what the material can do is a different story. That's why you have to be both creative and flexible.’

Semi made the first outfit in the collection from dozens of pieces of fabric. The edges of the pieces weren’t finished but were hand-hemmed after sewing.

The word ‘collection’ is important to the trio, who clearly have lofty goals. ‘We make products of the highest quality, and we’re aiming for the international luxury fashion market,’ says Semi.

Luxury is prestige

The next step is to get funding to develop and expand the collection. The team already has promising ideas about how to make the colours water resistant. They also plan to test the performance of different wood species and the use of wood processing by-products.

‘Our next step is to investigate how durable the colour is on a wood filament surface and whether the nanocellulose could be added to the surface of the crystals by machine, which would make it easier to scale up,’ says Klockars.

The trio say that the key to development is close contact and an atmosphere where you can ask and say anything you like. ‘The flexibility that Anna mentioned is also very important. Many things don't work out, or the concept may work, but you have to take many more steps to get there,’ says Yau, adding with a laugh that she currently has the 3D printer in her home.

‘This will take so long to print on this device that we can’t leave it at the institute. At the same time, it’s good to work on my dissertation.”

There are a few other groups around the world developing sparkly wood. One is focused on effect pigments, another on sequins. No one else is known to be making wooden crystals, and the Aaltonians’ work is garnering interest from companies around the world. Yau, Semi and Klockars were recently contacted by a major credit card company that wanted Shimmering Wood as a coating for the top tier of their credit card.

‘It would have been great, but the timeframe and scale were impossible,’ says Yau.

For the trio, aiming for the luxury fashion industry is both a rational and a value-based choice. Innovative materials are expensive, especially at the beginning, and multinational luxury fashion companies are interested in sustainable concepts and have the budget to explore them.

If all goes well, in five years the trio hopes to be working with a major company or manufacturing wood crystals in their own studio for the world's top brands.

But luxury is first and foremost about valuing the material and respecting nature, the trio say. It's not about using glittery eco-colours to sell more disposable goods. ‘Nature is increasingly becoming a luxury. Our aim is to use Finland's forests to make products with a long life that are valuable – things we don't want to throw away but will cherish,’ says Yau.

Parallel paths: Designer and materials scientist conjure up glimmering colours out of wood

Designer Noora Yau and materials scientist Konrad Klockars have used wood to conjure up a colour, which is transparent yet glows like a copepod in shallow water. The pair’s good chemistry and open attitude towards asking silly questions is a great help in their work.